Recommendation: 在每个推进系统上安装经认证的紧急停止装置;在舵位处张贴清晰可见的书面说明;控制装置应能让掌舵者轻易操作;这能确保快速反应,降低失控风险,拯救生命;支持航行安全;此措施还能通过提供清晰的书面合规证明来满足受访者的需求。.

受访者 您是在暗示,海上发生的许多事故都涉及失控推进期间的失控;认证设备可以减少总体伤害;来自当局的书面数据支持这一观点,表明需要确保每艘船只都配备该设备;这一回应也反映了他们导航团队的观点。.

制造商应为船只配备集成于推进系统中的简易关闭机制;维护检查应验证书面标牌;舵位标签;拖曳设备就绪;船员穿着救生衣迅速反应;远程监控在设备发生故障时提醒有关部门;通过快速响应,海上作业人员的生命将更安全。.

在航行路线上,跨舰队保护至关重要;船上人员的需求需要统一的规则;检查可确保有足够的能量储备来应对失控事件;掌舵者只需一个动作即可触发关闭;拖曳作业、渔船、客运轮渡都将受益于此保护;此措施有助于甲板和水上的安全。.

这 转变反映了受访者的声音,他们强调实际步骤;提案应包括实践培训;书面演练;码头边的绩效衡量;确保船员知道如何使用该系统,包括离港前的测试;监督员必须验证每个穿戴救生衣的人是否已准备好在几秒钟内做出反应;船东报告合规情况,详细说明维护措施;侧重于安全,保护生命。.

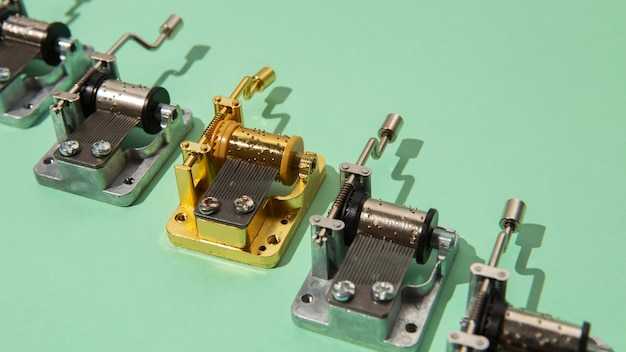

实用合规和安全:在各种发动机上实施ECO开关

建议:在推进系统上实施经过船级社批准的ECO电路,并明确标识与船体编号、尺寸等级和功率等级相关联;确保主要安全功能存在并已准备就绪,尤其是在一月至十二月的周期内。.

许多船只和船员已经支持这一路径;一项指令明确了所需步骤,降低了因不匹配造成的风险,防止了非标准组件引发的问题,并确保在检测到异常时,经过警卫批准的声音警报会启动。.

制定一个切实可行的推广计划:绘制每个工艺的尺寸图,确定从点火访问到ECO线路的主要链接,并组装一个单一的、可扩展的工具包,该工具包保持获得守卫批准,并可使用基本工具进行安装。包括一个清晰的测试协议,涵盖1月至12月周期内的关键场景。.

文档和验证:生成测试日志,向船东展示结果以描述发生了什么以及完成了什么,并用警卫批准的标签标记单元;保持与船艇类别(捕鱼、娱乐、商业等)和船舶编号相关的完全可见性。.

风险应对:当故障触发警报时,自动断电;船民收到清晰的音频信号(发声)和视觉指示;一些团体反对快速变化,但许多人支持更安全的操作。.

监管结果:身份识别记录能够实现快速审计;因错过集成而导致的事故数量下降;可以生成指南链接,并在一个动态文档中保持更新;一月至十二月的节奏确保与警卫批准的标准和利益相关者(尤其是渔船和商业船队)的期望保持持续一致,从而解决潜在问题。.

适用范围:哪些发动机和车辆必须使用切断开关

在操作前,船东必须在用于水上娱乐的船只上的推进电机上配备一个安全断路装置。.

范围包括汽油或柴油发动机驱动的船舶,涵盖游艇、小型渔船、轻型商用船只。.

规模阈值因司法管辖区而异;但是,随附的第 12 版董事会指南提供了一个基准。.

建议对现有车队进行潜在的改造;请参考随附的指导原则,并在咨询期间收集运营商的意见。.

确定最低保护功能:连接到电源的保护装置,设计为在分离瞬间触发,防止危险动作。.

在检查期间,设备上的白色标签有助于快速识别;附上的标牌会告知操作员在哪里验证状态。.

需要董事会监督;船东责任包括培训船员、记录措施、注明尺寸等级、灭火器可及性。.

安装期间,告知维护人员验证布线、防护罩间隙、功能测试;完成检查确认符合性。.

飞机操作需要一个专用的电源系统断路器,在机动期间提供保护;请参阅随附的第12版指南。.

结论:规模、类型、用途各异;此方法可有效降低风险;请向董事会汇报结果。.

当然,负责人在场能倍增咨询的成功率;请告知船员行动方案、守卫位置。.

安装和挂绳放置:快速激活的最佳实践

在腰带或安全带的中间区域安装固定点,以便在水况恶劣、张力升高时,能够立即触及启动装置。这可以减少操作过程中的反应时间,并降低错过提示的风险——这在波涛汹涌的水域中至关重要。从而在紧急情况下提供更高的可靠性。.

如果空间和能见度允许,请选择右舷侧;确保系索路径避开甲板设备。必须保持舵手的视线,因为当缆绳被遮挡时会发生误读提示的情况,同时你要确认抓握牢固,允许单手完全拉动。.

长度很重要:选择0.8–1.2米的长度,以平衡触及距离和操控性。较长的绳索会增加在波浪中被装备或抛掷物缠住的风险,尤其是在渔线可能漂到安装区域附近的水域。.

通过空转进行安装验证,然后在轻微喷雾中进行受控测试;拉动系索时应立即启动,如果可能,装置应完全停止运动。.

许多地区的法律要求清晰的标签、定期检查和记录;请遵循1月至12月的相应指南,并确保状态指示器清晰地向船员显示。.

为了最大化性能,请在船上提供一份易于访问的安装细节手册;验证是否存在纠正措施计划,以应对您的情况中可能出现的调整;并减少培训课程中的歧义。.

| Aspect | Recommendation | Rationale |

|---|---|---|

| 锚定点 | 中段腰带/挽具 | 缩短触及时间;最大限度地减少钩挂 |

| 挂绳长度 | 0.8–1.2 米 | 平衡的触及范围;降低缠绕风险 |

| 侧面方向 | 能见度良好时,右舷优先。 | 更佳视线;减少甲板干扰 |

| 指标可见性 | 清晰、易读的标签或 LED | 高效的就绪状态验证 |

| 测试节奏 | 干运行,然后实测;每月检查 | 确保在机动过程中立即采取行动 |

测试协议:验证激活后发动机立即停止

建议:快速停用必须在主要安全机制启动后0.8秒内发生,并通过集成到已安装控制模块的有线测试线束进行验证。此定时与制造商规格相符;降低水域中的生命风险。装置尺寸;功率等级;布局影响定时。必须书面记录测试信息;存储信息;并通过咨询提供信息。.

另一要素包括与认证驾驶员代表进行的预测试验证;咨询记录在案;检查指示器的可见性。.

Measurement steps: trigger from the driver console; data logger records timestamps; ecosl size parameter influences interpretation of results; since test duration remains brief, comparison against the 0.8 second target proceeds promptly.

Safety considerations: testing occurs in controlled environments; extinguishers available; ventilation maintained; towing operations paused if misfire; starboard orientation used to align crew observations; visibility of indicators documented.

Post-test: if a discrepancy arises, comments from driver, consultant, certified staff recorded; written report documents primary findings; follow-up tests scheduled.

Regulatory Landscape: Regional Standards for Marine, Automotive, and Industrial Uses

Recommendation: harmonized mandates by the 12th month; Canada leads vessels policy; captain duties; board oversight; cabin safety; open disclosure of devices.

Regulatory taxonomy spans three domains: marine equipment codes; vehicle safety standards; industrial safety acts; laws guide design, testing, labeling; mandates require reporting; visual cues assist crew; extinguishers, distress devices displayed; length thresholds, date stamps drive audits; Canada collaborates with regional boards.

- Marine: laws mandate visible, visual display of safety equipment on vessels; cabin layouts require extinguishers mounted with clear placement; captain responsibilities documented; distress signals accessible; date of verification appears in the log; length thresholds determine equipment counts; open lines to the board; wearing life jackets in cabin; shipboard operations recorded; Canada collaborates with regional boards under the 12th month mandate.

- Automotive: laws mandate crash-test records; visual dashboards display warnings; devices labeled; date stamps on safety components; length of warranty cycles; require ongoing maintenance logs; Canada participates via federal, provincial agencies; people, operators, technicians must review indicators prior to operation.

- Industrial: laws address PPE, extinguishers distribution, distress signaling in facilities; devices displayed; logs maintained; 12th month deadlines; board oversight; plant managers responsible; Canada engages through industrial safety boards; visual cues inside facilities; open lines to maintenance crews.

In Canada, authorities date to implement harmonized model by the 12th month; this aims into reducing distress during operation; the board reviews visual cues within cabins, vessels, boats; captain duties represented by checklists referencing extinguishers, devices, length thresholds; youre role is to verify adherence before each voyage.

Character shown by this regime is a focus on people safety; moment of alignment across vessels, boats, cabins; would reduce distress during operation; therefore training aligns with open inspection; into this framework, extinguishers, devices, laws are represented visually; date stamps confirm length thresholds; youre role is to verify status before each voyage.

Maintenance and Lifespan: Inspecting, Replacing, and Documenting the Lanyard

Inspect the lanyard after every voyage; replace immediately if there is visible wear, fraying, softening, or a damaged attachment mechanism.

Check loop integrity; verify mounting hardware; confirm accessibility of the lanyard’s attachment mechanism at the board side; confirm total length within acceptable limits.

Replace after years of use that show wear; choose a certified model; use only original attachment components; example: a Canada-based supplier with a verified certification reduces risk considerably.

Document all actions in a maintenance log; note date, model, serial, installation site; keep the file accessible on the vessel board; pre-publication attachment accompanies the record; this simply strengthens traceability during inspections.

Develop a replacement cycle; depending on usage times, environmental exposure, installation vibration, total load; potentially require replacement every few years; store retired units in a plane-labeled container within a well-ventilated area.

Questions asked by boat owners cover protection about themselves; procedures that require regular checks exist; certified guidance exists; note examples from Canada; whether a given local regulation remains a point to discuss; opposed viewpoints exist in some jurisdictions; crew may agree on a common standard; this standard provides enough protection; a practical example from Canada widely implemented.

Engine Cut-Off Switch Requirement – A Go-Ahead for Safer Engines and Compliance">

Engine Cut-Off Switch Requirement – A Go-Ahead for Safer Engines and Compliance">