Recommendation: внедрить сертифицированное устройство аварийного отключения для каждой двигательной установки; письменные инструкции должны быть видны у руля; управление должно быть доступно для человека, находящегося за штурвалом; это обеспечивает быстрое реагирование, снижает риск неконтролируемого движения, спасает жизни; поддерживает безопасность навигации; эта мера также отвечает потребностям респондентов, предоставляя четкое письменное подтверждение соответствия.

респонденты предполагаете, что многие аварии на море связаны с потерей контроля во время неконтролируемого движения; сертифицированные устройства уменьшают общий ущерб; письменные данные от властей подтверждают эту точку зрения, указывая на необходимость обеспечить наличие устройства на каждом судне; этот ответ также отражает мнение их навигационных команд.

Производители должны оснащать суда простым механизмом отключения, интегрированным в двигательную установку; проверки технического обслуживания подтверждают наличие письменных табличек; маркировку рулевого управления; готовность буксировочного оборудования; экипажи, надевшие спасательные жилеты на ноги, быстро реагируют; удаленный мониторинг оповещает власти в случае отказа устройства; жизни в море остаются в большей безопасности благодаря быстрому реагированию.

На навигационных маршрутах защита межфлотского взаимодействия имеет значение; потребности людей на борту их судов требуют последовательных наборов правил; проверки гарантируют достаточные запасы энергии для действий во время нештатной ситуации; человек у руля запускает отключение одним движением; буксировочные операции, рыболовные суда, пассажирские паромы выигрывают от этого покрытия; эта мера способствует безопасности на палубе и на воде.

Это переход отражает мнения респондентов, которые подчеркивают практические шаги; предложение должно включать практическое обучение; письменные тренировки; измерение производительности в доке; обеспечение того, чтобы экипажи знали, как использовать систему, включая тест перед выходом из порта; руководители должны убедиться, что каждый человек, носящий СПЖ, готов среагировать в течение нескольких секунд; владельцы сообщают о соблюдении требований, подробно описывая действия по техническому обслуживанию; акцент на безопасности, защите жизни.

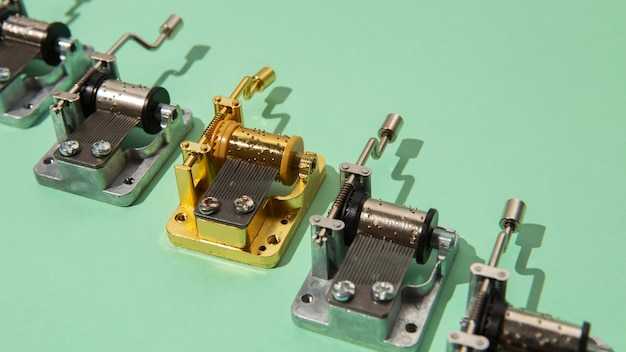

Практическое обеспечение соответствия и безопасности: внедрение ECO-переключателей в двигателях

Рекомендация: внедрить утвержденную охраной окружающей среды схему ECO во всех силовых установках с четкой идентификацией, привязанной к номерам корпусов лодок, классам размеров и мощностям; обеспечить наличие и готовность основной функции безопасности, особенно в течение циклов январь-декабрь.

Многие лодки и владельцы уже поддерживают этот путь; мандат проясняет необходимые шаги, снижает риск, вызванный несоответствиями, защищает от проблем, вызванных нестандартными компонентами, и гарантирует, что одобренный береговой охраной звуковой сигнал тревоги активируется при обнаружении аномалии.

Разработайте практический план развертывания: составьте карту размеров каждого судна, определите основную связь от доступа к зажиганию до цепи ECO и соберите единый масштабируемый комплект, одобренный охраной и устанавливаемый с помощью базовых инструментов. Включите четкий протокол тестирования, охватывающий ключевые сценарии в циклах с января по декабрь.

Документация и валидация: генерировать журналы испытаний, представлять результаты владельцу для описания произошедшего и выполненных работ, а также маркировать агрегаты бирками, одобренными службой охраны; поддерживать полную прозрачность, связанную с категорией судна (рыболовное, прогулочное, коммерческое и т.д.) и номером судна.

Реагирование на риск: при возникновении неисправности, вызывающей срабатывание сигнализации, происходит автоматическое обесточивание; судоводители получают четкий звуковой сигнал (звуковоспроизводящий) и визуальный индикатор; некоторые группы выступали против быстрых изменений, однако многие поддерживают более безопасную работу.

Результаты регулирования: идентификационные записи обеспечивают быстрые проверки; количество инцидентов, вызванных пропущенной интеграцией, снижается; можно сгенерировать ссылку на руководства, а обновления хранить в актуальном документе; январско-декабрьский ритм обеспечивает постоянное соответствие стандартам, утвержденным охраной, и ожиданиям заинтересованных сторон, особенно со стороны рыболовецких судов и коммерческих флотов, решая потенциальные проблемы.

Область применения: Какие двигатели и транспортные средства должны использовать выключатель массы

Перед началом эксплуатации владелец обязан оснастить гребные двигатели на судах, используемых на водных объектах для отдыха, предохранительным устройством отключения.

В область применения входят суда, приводимые в движение бензиновыми или дизельными двигателями, включая прогулочные суда, небольшие рыболовные суда и легкий коммерческий флот.

Пороговые значения размеров отличаются в зависимости от юрисдикции; однако прилагаемое руководство 12-го издания от совета предлагает базовый уровень.

Рекомендуется рассмотреть возможность модернизации существующих парков; пожалуйста, ознакомьтесь с прилагаемыми инструкциями и соберите комментарии операторов в ходе консультаций.

Определите минимальные функции защиты: охранный элемент, связанный с источником питания и предназначенный для срабатывания в момент разъединения, предотвращающий опасные движения.

Во время осмотров белая маркировка на устройстве помогает быстро его идентифицировать; прикрепленные таблички указывают операторам, где проверять состояние.

Требуется надзор совета директоров; ответственность владельца включает обучение экипажа, документирование мер, указание класса размера, доступность огнетушителя.

Во время установки, поручите обслуживающему персоналу проверить проводку, зазоры ограждений, функциональные тесты; выполненные проверки подтверждают соответствие.

Для обеспечения работы самолета требуется специальный разъединитель для энергосистем, обеспечивающий защиту во время маневров; см. руководство в приложении, 12-е издание.

В заключение: размер, тип и использование варьируются; этот подход обеспечивает эффективное снижение рисков; пожалуйста, сообщайте о результатах совету директоров.

Конечно, присутствие владельца умножает успех во время консультации; пожалуйста, расскажите команде о перемещениях, позициях охраны.

Монтаж и размещение темляка: лучшие практики для быстрой активации

Установите точки крепления на ремне или страховочной привязи в средней части тела, чтобы активация была в пределах вашей досягаемости сразу же при нарастании напряжения на неспокойной воде. Это сокращает время реакции во время маневров и снижает риск пропустить сигнал, что имеет значение при сильной качке. Это обеспечивает большую надежность в чрезвычайных ситуациях.

Пожалуйста, выбирайте правый борт, если позволяют место и видимость; убедитесь, что веревка не зацепляется за палубное оборудование. Необходимо поддерживать видимость с рулевого, потому что неверное прочтение сигнала происходит, когда линия обзора закрыта, в то время как вы проверяете надежный захват, позволяющий полностью натянуть веревку одной рукой.

Длина имеет значение: выбирайте длину в диапазоне 0,8–1,2 м для баланса между досягаемостью и контролем. Более длинные стропы увеличивают риск зацепиться за снаряжение или выброшенные предметы во время волн, особенно в водах, где рыболовные лески могут дрейфовать близко к месту установки.

Убедитесь в правильности установки с помощью холостого прогона, затем проведите контролируемый тест с небольшим распылением; активация должна происходить немедленно при вытягивании шнурка, при этом устройство должно останавливать движение полностью, если это возможно.

Законы во многих местностях требуют четкой маркировки, периодических проверок и документации; пожалуйста, следуйте соответствующим указаниям в период с января по декабрь и убедитесь, что индикатор состояния четко отображается для экипажа.

Для максимальной производительности изложите детали установки в доступном руководстве на борту; убедитесь в наличии плана корректирующих действий, учитывающего возможные корректировки в ваших ситуациях, и уменьшите количество неясностей в учебных занятиях.

| Aspect | Recommendation | Rationale |

|---|---|---|

| Точка привязки | Поясной ремень/страховочная привязь | Сокращает время вытягивания; минимизирует зацеп. |

| Длина ремешка | 0,8–1,2 м | Сбалансированная досягаемость; снижает риск запутывания |

| Боковая ориентация | При ясной видимости следует предпочитать правый борт. | Улучшенная прямая видимость; уменьшает помехи на палубе. |

| Видимость индикатора | Чёткая, разборчивая маркировка или светодиод | Эффективная проверка готовности |

| Частота тестирования | Прогон вхолостую, затем испытание под нагрузкой; ежемесячные проверки | Обеспечивает немедленные действия во время маневров |

Протоколы тестирования: проверка немедленной остановки двигателя при активации

Рекомендация: Быстрая деактивация должна произойти в течение 0,8 секунды после активации основного предохранительного механизма, что подтверждается проводным испытательным стендом, интегрированным с установленным модулем управления. Данная задержка соответствует спецификациям производителя; снижает риск гибели людей на воде. Размер устройства; номинальная мощность; компоновка влияют на время. Информация о результатах испытаний должна быть записана; сохранена; предоставлена для ознакомления.

Другой элемент включает предварительную проверку с участием сертифицированных представителей водителей; задокументированные консультации; проверенная видимость индикаторов.

Measurement steps: trigger from the driver console; data logger records timestamps; ecosl size parameter influences interpretation of results; since test duration remains brief, comparison against the 0.8 second target proceeds promptly.

Safety considerations: testing occurs in controlled environments; extinguishers available; ventilation maintained; towing operations paused if misfire; starboard orientation used to align crew observations; visibility of indicators documented.

Post-test: if a discrepancy arises, comments from driver, consultant, certified staff recorded; written report documents primary findings; follow-up tests scheduled.

Regulatory Landscape: Regional Standards for Marine, Automotive, and Industrial Uses

Recommendation: harmonized mandates by the 12th month; Canada leads vessels policy; captain duties; board oversight; cabin safety; open disclosure of devices.

Regulatory taxonomy spans three domains: marine equipment codes; vehicle safety standards; industrial safety acts; laws guide design, testing, labeling; mandates require reporting; visual cues assist crew; extinguishers, distress devices displayed; length thresholds, date stamps drive audits; Canada collaborates with regional boards.

- Marine: laws mandate visible, visual display of safety equipment on vessels; cabin layouts require extinguishers mounted with clear placement; captain responsibilities documented; distress signals accessible; date of verification appears in the log; length thresholds determine equipment counts; open lines to the board; wearing life jackets in cabin; shipboard operations recorded; Canada collaborates with regional boards under the 12th month mandate.

- Automotive: laws mandate crash-test records; visual dashboards display warnings; devices labeled; date stamps on safety components; length of warranty cycles; require ongoing maintenance logs; Canada participates via federal, provincial agencies; people, operators, technicians must review indicators prior to operation.

- Industrial: laws address PPE, extinguishers distribution, distress signaling in facilities; devices displayed; logs maintained; 12th month deadlines; board oversight; plant managers responsible; Canada engages through industrial safety boards; visual cues inside facilities; open lines to maintenance crews.

In Canada, authorities date to implement harmonized model by the 12th month; this aims into reducing distress during operation; the board reviews visual cues within cabins, vessels, boats; captain duties represented by checklists referencing extinguishers, devices, length thresholds; youre role is to verify adherence before each voyage.

Character shown by this regime is a focus on people safety; moment of alignment across vessels, boats, cabins; would reduce distress during operation; therefore training aligns with open inspection; into this framework, extinguishers, devices, laws are represented visually; date stamps confirm length thresholds; youre role is to verify status before each voyage.

Maintenance and Lifespan: Inspecting, Replacing, and Documenting the Lanyard

Inspect the lanyard after every voyage; replace immediately if there is visible wear, fraying, softening, or a damaged attachment mechanism.

Check loop integrity; verify mounting hardware; confirm accessibility of the lanyard’s attachment mechanism at the board side; confirm total length within acceptable limits.

Replace after years of use that show wear; choose a certified model; use only original attachment components; example: a Canada-based supplier with a verified certification reduces risk considerably.

Document all actions in a maintenance log; note date, model, serial, installation site; keep the file accessible on the vessel board; pre-publication attachment accompanies the record; this simply strengthens traceability during inspections.

Develop a replacement cycle; depending on usage times, environmental exposure, installation vibration, total load; potentially require replacement every few years; store retired units in a plane-labeled container within a well-ventilated area.

Questions asked by boat owners cover protection about themselves; procedures that require regular checks exist; certified guidance exists; note examples from Canada; whether a given local regulation remains a point to discuss; opposed viewpoints exist in some jurisdictions; crew may agree on a common standard; this standard provides enough protection; a practical example from Canada widely implemented.

Engine Cut-Off Switch Requirement – A Go-Ahead for Safer Engines and Compliance">

Engine Cut-Off Switch Requirement – A Go-Ahead for Safer Engines and Compliance">