Opt for a bespoke hardtop layout on this 80m Nobiskrug to maximize outdoor living and year‑round comfort. These design choices create a contemporary silhouette with clean lines and generous deck space that invites effortless socializing while preserving performance and efficiency.

According to the stated specs, the vessel will reach 80 meters in length, with a broad beam and generous displacement that support expansive exterior decks and a refined interior volume. The interior is bespoke and modular, providing options that are ideal for both private use and charter programs. These arrangements offer a layout type that suits the owner’s needs and crew operations, which gives you clear flexibility in day-to-day use.

From concept to launch, the timeline follows a clear, phased path: design refinement, naval approvals, steel cutting, hull assembly, outfitting, deck and superstructure integration, launch, and sea trials. A representative project plan maps these milestones, and the current sequence emphasizes parallel work streams to reduce lead times. In the project chat, whats driving decisions here is owner flexibility and charter versatility. The team will implement a modular, scalable outfitting approach to provide flexibility for future upgrades. Ever mindful of quality, the schedule aims to stay tight without compromising safety.

On deck, the hardtop concept creates a convertible sun deck that can close down in rough seas, while the main salon benefits from large windows and a contemporary aesthetic. The exterior lines stay restrained, which show the balance between speed, stability, and fuel efficiency. Inside, a current design language blends natural materials with advanced control systems, delivering a calm providing ambiance for long stays and intimate gatherings. The owner’s deck is paired with a discreet crew zone to keep operations smooth without intruding on guest spaces.

To buyers and operators, demand a hull form and propulsion package that delivers steady performance with minimal noise at cruise. Ask for a comprehensive interior plan in the project chat and a data‑driven maintenance and parts schedule that remains robust across charter cycles. The program aims to provide a platform that can adapt to evolving needs and future tech upgrades without compromising guest comfort or crew efficiency.

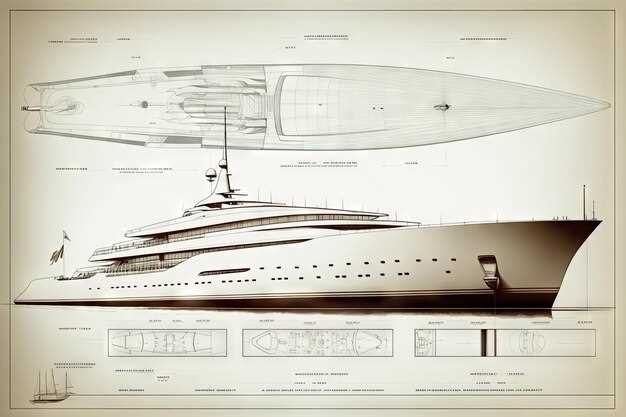

Hull Type and Structural Blueprint

Opt for a fully steel, full-displacement hull with a bulbous bow and integrated stabilisation as the primary hull form. This choice minimizes time at sea, lowers risk during heavy seas, and supports high-end performance for an 80m superyacht. The configuration delivers steady fuel efficiency and predictable seakeeping for long passages and entertaining guest experiences.

Structure and areas: The hull uses a double-bottom steel shell with continuous keel and closely spaced frames to handle wave impact and reduce vibrations. A welded, seamless hull girder forms a robust backbone that transfers loads to watertight bulkheads, creating dedicated areas for machinery, fuel, and guest spaces. The aluminium superstructure above keeps weight low and enables a contemporary silhouette while preserving stability at speed.

Stabilisation and step sequence: A modern stabilisation system uses active fins and gyroscopic controls to maintain comfortable roll angles at rest and underway. The structural blueprint follows a step sequence, using modular assembly that permits later changes to guest areas or service spaces, aligning with standard safety margins and special requests. This approach reduces risk during construction and testing and provides an example of how maintenance windows can be planned.

Entertaining spaces and images: The main deck integrates entertainment zones with flexible seating and projecting images for lectures or screenings, without compromising hull strength. The design keeps service routes separate from guest flows, maintaining safety and comfort in all areas.

Management and lifecycle: The blueprint supports personal crew workflows with clearly defined areas for engine rooms, fuel, ballast, and guest services, reducing downtime and improving time to repair. Innovations in corrosion protection, coatings, and modular components extend service intervals, enabling later upgrades and standardization across systems. This approach makes the hull easier to maintain and ready for contemporary refits.

Hull Material and Construction Method

Choose a steel hull with an aluminum superstructure built in modular blocks for the 80m Nobiskrug project to maximize durability, access to machinery, and long-range efficiency. This approach will provide reliable service on long cruises.

Materials selection balances bottom strength, corrosion resistance, and space for ballast and fuel tanks. The hull uses marine-grade steel for the bottom and sides, while the upper structure uses 6xxx-series aluminum to reduce above-water weight. This combination yields high stiffness and improved stability without a heavy lift in the bottom region.

Construction method centers on block-by-block assembly. Panels are welded to frames and stringers to form a rigid shell that tests well before launch. Yards in cannes and other major centers pre-fit modules with systems, enabling faster assembly in the cradle and easier access for installation. Double-bottom tanks and ballast compartments balance weighing across the hull, while the superstructure attaches to stiffeners that support panoramic windows and the luxury interiors.

As stated by Nobiskrug, the material system aligns with class requirements, with non-destructive testing and hydrostatic checks to confirm integrity. The materials choice focuses on durability and longevity, with epoxy coatings and corrosion protection guiding maintenance. The design emphasizes above-waterline efficiency, smoother hull lines, and refined control in turns, supporting long-range operations and owner comfort. The plan also respects country regulations for safety and hull design.

Example of a materials solution: a steel hull with aluminum superstructure, epoxy-coated panels, sandwich deck cores, and composite fairing. This type provides access to internal services, reduces overall weight, and improves fuel efficiency. The approach fits Nobiskrug’s brand and matches the gross tonnage targets for a yacht of this size, with cannes-friendly supply chains well positioned to support the project.

Keel Design and Hydrodynamic Profile

Implement a sculptural keel with a deep bulb and an open-wing extension to reduce pitching and increase lift at cruise, paired with a diesel-electric propulsion package and extra margin for reliability in open-water conditions for yachts of this size, which benefits fuel efficiency.

-

Keel geometry and ballast

A long, slender keel with a rounded bulb keeps the center of gravity low while allowing ballast within a compact shell. Target ballast in the range of 25–35% of displacement, with a stable natural frequency across ~10–18 knots, and tailored for particular load scenarios. Keep clear boundaries between ballast and hull to simplify inspection and service access.

-

Hydrodynamic integration

The trailing-edge winglets provide downwash management and reduce stern trim changes under gusts. A triple-wing strategy can spread lift and control wake across different speed regimes, while maintaining a sculptural silhouette that blends with the hull lines.

-

Propulsion and power management

The diesel-electric package supports engine room flexibility and smoother torque delivery. A triple-generator array offers redundancy and load sharing, while smart controls maintain balanced shaft torque. Data from sensors feeds a phone-based interface in the wheelhouse for quick checks by the engineer team and support from gregory at rondal for mounting and ergonomics.

-

Appendages and hull interaction

Keel-to-hull interfaces receive low-friction coatings and round fillets to minimize separation. rondal fittings enable precise alignment of appendages, while the sculptural keel form reduces vibration transmission to the superstructure.

-

Testing, information, and thresholds

Define testing thresholds early and gather information from sea trials to adjust trim, ballast, and wing angles. Open-water runs test stability, speed, and drag across current sea states; data is interpreted by the engineer team to refine the profile before final build. The process currently uses a country-specific compliance checklist to ensure all local standards are met.

Stability, Ballast System, and Safety Margins

Recommendation: adopt a diesel-electric propulsion package paired with an active ballast system featuring four ballast tanks with a combined capacity of 260–320 m3, four high-capacity ballast pumps rated at about 150 m3/h each, and a fast-responding control loop that adjusts trim within 60 seconds of a sea-state change. Tailored to nobiskrugs’ 80 m profile, it uses the latest control algorithms from the designer to keep motion gentle for guests while preserving captain control underway.

Ballast layout integrates fore and aft tanks plus two wing tanks for precise heel and trim management. Four independent pump trains with a dedicated ballast generator ensure operation even if one line is offline. A robust sensor suite–gyros, accelerometers, and water-flow meters–feeds the stability model and is monitored from a glass-walled bridge area so guests and owners can observe the system in action. источник data from recent trials supports this approach and guides tuning as weight and weather evolve, so the system remains responsive over time.

Safety margins are built into the design with ballast reserve beyond peak need, targeting 12% spare capacity, dual pump trains, and an emergency ballast pump paired with energy storage. The arrangement adheres to established standards and includes routine sea trials, automated fail-safe modes, and manual overrides for the captain when conditions demand immediate action. This approach reduces risk during late-season operations and aligns with both owners’ expectations and crew training, aligning with time-tested practices aboard high-profile yachts.

| Element | Function | Примечания |

|---|---|---|

| Diesel-electric propulsion | Power for propulsion and ballast pumps; minimizes vibration | Integrated with stability control; requires generator redundancy |

| Active ballast tanks (fore, aft, port, starboard) | Trim and heel control; rapid response | Controlled via SCADA; flows tailored to payload |

| Pumps and piping | Move ballast water between tanks; rapid adjustments | Four lines; ~150 m3/h per line; redundant trains |

| Sensors and control system | Gyro, inclinometer, motion sensors; integrated stability model | Bridge display; remote monitoring; supports eventual autonomous tweaks |

| Safety and margins | Failure-safe modes; backup ballast pump; energy storage | Meets standards; validated in sea trials |

| Источник data | Reference for model accuracy | Derived from latest trials and supplier specifications |

Glimpse into the future shows improvements in glass-walled observer areas and enhanced guest comfort, while the core stability strategy remains anchored in a robust ballast backbone. Whats next for stability planning will unfold through underway tests and later sea trials, as the design evolves with time and feedback from the captain and owners, ensuring the system holds beyond the initial build phase.

Deck Layout and Structural Redundancies

Install two independent engine rooms and a split fuel system to guarantee propulsion and essential systems remain operational during delivery and live sailing.

Clear zoning on the 80m Nobiskrug project supports efficient maintenance, guest comfort, and safe evacuation. The deck plan targets a tonnage‑aware balance, with areas allocated to guest experiences, crew support, and technical durability, while keeping service corridors on standby for rapid access during major events such as Cannes showcases or private festival gatherings.

- Sundeck – Area approximately 190 m2. Features a 6×3 m pool, sun lounges, shaded dining for up to 20 guests, and a weather‑protected bar zone; connections to the upper deck optimize flow for outdoor shows and art artefacts display needs.

- Main deck – Area 350–420 m2. Includes formal dining for 18–26, a park‑like salon, and a wraparound terrace; lift access ensures seamless guest circulation between levels.

- Bridge deck – Area 120–150 m2. Wheelhouse and pilot spaces adjacent to a panoramic sky lounge; quick link to the main foyer and outdoor seating areas for spontaneous gatherings.

- Upper deck – Area 220–260 m2. Deluxe guest suites with private terraces and a dedicated fitness/wellness area; external decks extend the visual reach for parties or small exhibitions.

- Lower deck – Area 400–500 m2. Crew quarters, galley and mess, medical room, laundry, and service corridors; robust segregation from guest regions maintains privacy and operational efficiency.

- Tender/Technical deck – Area 110–130 m2. Garage for tenders and toys, crane reach, workshop spaces, and separate access for supply runs; designed to keep fuel, tools, and artefacts secure during shows and deliveries.

Structural redundancies safeguard critical functions across major domains. Prioritize segregation and rapid transfer capability to prevent single‑point failures from impacting guest comfort or delivery milestones.

- Propulsion redundancies: two independent engine rooms with duplicate shaft lines and cross‑connected propulsion controls; a dedicated backup propulsion path can engage without interrupting guest operations.

- Power and electrical: dual gensets per plant, two separate electrical buses, and automatic transfer switches to guarantee uninterrupted lighting, navigation, and climate control.

- Fuel and water systems: parallel fuel services with independent transfer lines to critical systems; redundant filtration and pump loops reduce risk during long deliveries or blue‑water passages.

- HVAC and pressurization: two fully separated climate loops with independent ductwork and sensor networks; dedicated zones for crew and guests preserve comfort under load changes.

- Steering and navigation: dual rudders paired with independent steering controls; a backup steering computer ensures control continuity if one channel fails.

- Fire safety and watertight integrity: redundant fire suppression circuits, extra bulkheads, and segmented compartments to limit flood spread; constant readiness for rapid isolation during operations or shows.

- Communications and data: two independent comms paths (satcom and terrestrial fallback) with shielded fibers; ring topology preserves connectivity during port calls or tender cycles.

For the custom scope, Nobiskrug planners map weight, stability, and serviceability around the noted areas and forté of robust redundancy. The approach aligns with a disciplined delivery plan, ensuring the vessel remains operable under demanding schedules and during world‑class events. If you need specifics on finishes or equipment packages, contact the project team to align on a contract and purchase path that fits your timelines, including on‑site tests and sea trials scheduled around major show windows in Cannes or similar venues. This strategy also supports showing the vessel as a turnkey asset, with unique artefacts and interior accents ready for presentation on the world stage.

Watertight Integrity and Maintenance Accessibility

Adopt a formal watertight integrity program with a weekly checklist and a mobile access plan that travels with the yacht through port calls. For the nobiskrugs 80m project, the master and crew run direct tests on all watertight boundaries, from forepeak to lazarette, and record results in a centralized log accessible via phone for the bridge and engineering spaces. This approach has been tailored for rapid fault isolation, reducing downtime and exposure to water ingress during sea trials and busy schedules. For a суперяхта of this class, start every season with a fresh seal audit and a short парус state trial to validate performance.

Key inspections target three areas: distinctive bulkhead alignments, стекло и hardtop transitions, and door/hatch seals. Each bulkhead features a paired set of gaskets and a redundant closure path so a single seal fault does not breach the integrity. The cutting-edge door actuators provide rapid closure with tactile feedback, while стекло panels use stainless frames and anti-slosh bolts to withstand spray and wind. A gross assessment of hull penetrations ensures that even small lines are tested for leakage under simulated sea states, and the crew uses парус handling motions to test movements without stressing the structure.

Maintenance accessibility drives the layout: remove one panel, reveal hoses, cables, and insulation; the hardtop interfaces and стекло seams are paired with accessible fasteners so technicians can work without removing furnishings from adjacent spaces. This approach comes with a maintenance promise to the owner and offers a festival-friendly setup for shore-side events. The страна build in Germany underpins a robust supply chain for components like locks, pumps, and sensors offered by the yard and marine engineers; nobiskrugs standards guide these choices.

Operationally, the plan uses direct coordination with the брокер network to track warranty items and service intervals, ensuring issues are flagged at the earliest stage. A dedicated september milestone marks the handover of the initial maintenance bays and the testing protocol to the owner’s team, aligning with master-level safety goals and a clear escalation path. The design creates a resilient system that supports guest comfort, with sensors logging humidity and door movement to avoid false alarms during events and voyages.

When a fault is detected, the crew follows a direct, pre-defined script to isolate the affected zone, re-close the bulkheads, and notify the chief engineer. The result is a reduced risk of water ingress, smoother guest experiences, and a maintenance cycle that respects the vessel’s distinctive design language and country heritage. With ongoing reviews, the yacht’s watertight system remains accessible for updates, and the team can host a casual inspection for a festival atmosphere without compromising safety or security.

80m Nobiskrug Superyacht to Be Built – Specs, Timeline, and Design">

80m Nobiskrug Superyacht to Be Built – Specs, Timeline, and Design">