Start the season with a precise hull inspection and a secured upkeep plan covering outboards, navtec, and interlux protection. This approach minimizes downtime, preserves performance, and gives captains a clear reference for service windows.

Our 수상 수상 team operates across the area and maintains vessels 전체 the season, with a pool of specialists ready for urgent dockside work. From hull surveys to deck fittings, we secure components that captains rely on, including shaft alignment and fuel-system integrity, guided by источник in the region for best practices that require strict adherence.

Request a detailed quote within 24 hours and check availability across your area. Our coordinators can align on-site or dockside work with sailing plans, minimizing downtime, and thats a streamlined process that maintains transparency in pricing.

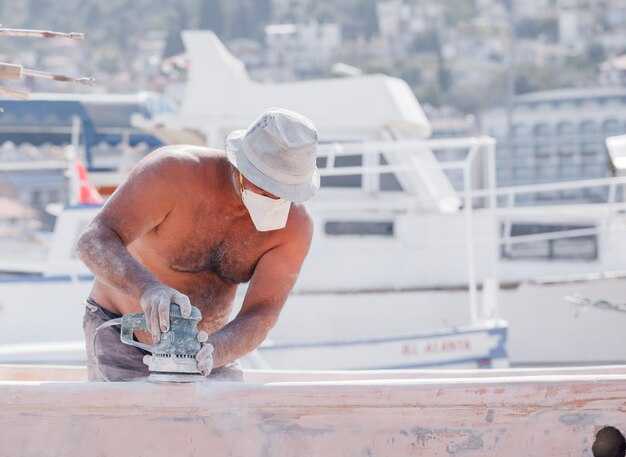

For larger programs, we map hull and deck alterations that captains plan before peak season there, with attention to hull coatings from interlux and protective measures for salt and sun, whether the vessel sits by a beach or at the pool, and we assess cabin carpet wear and non-slip mats to ensure crew safety.

In all tasks, we keep the focus on communication, with clear availability updates, a straightforward quote, and documented steps that ensure secure operations across the region there.

Hinckley Yacht Services: Premium Yacht Maintenance, Refits & Concierge Care in Portsmouth

Schedule a full upkeep assessment in Portsmouth before the peak boating season to protect power systems, engines, and water supply, ensuring reliable performance for homeowners and families during vacation time.

During the visit, technicians inspect diesels and Yamaha engines, verify power output at idle and under load, and perform a replacement parts check for wear items such as filters, impellers, belts, and hoses. Sea trials confirm propulsion responsiveness and steering control, with checks of night navigation lighting for safe operation.

To meet policy requirements and eligibility for preferred slots, we tailor a plan that covers location, mooring type, and usage. Our services are available throughout Portsmouth, with on-site support and remote diagnostics to mitigate issues before they escalate.

Interior upgrades for settees and upholstery refresh comfort after days spent at the beach or by the pool, while exterior work includes hull inspections, coatings, and electrical checks to prevent water ingress and ensure safety for families and kids aboard.

Start by meeting our team at the marina; booking is flexible to fit the needs of homeowners and families, with night slots and weekend windows to align with vacation plans. This approach keeps the juice flowing through the electrical system and ensures power remains available when you need it most.

Tailored Maintenance Schedule for Hinckley Yachts in Portsmouth

Begin with a quarterly servicing audit, aligned to variable sailing plans in Portsmouth’s waterfront yards. Start with a full hull inspection, zincs and anodes check, rudder bearings, and rigging review, also a 30-day check on outboards where fitted. Use a Microsoft-enabled log to track needs, price quotes, and available services.

Seasonal schedule: Q1 pre-season servicing (Jan–Mar) covers electrical health, battery status, charging circuits, steering gear, and anchor windlass. Q2 mid-season servicing (Apr–Jun) targets hull cleaning, zinc replacement, propellers, and stern gear. Q3 post-season review (Jul–Sep) reviews engine hours, cooling and filters, lubrication. Q4 off-season provisioning (Oct–Dec) stocks spare parts, tunes rigging, and services tenders. Workload varies over the season to stay within ideal limits.

Customization by models and use: models with light usage may require servicing every six months, whereas high-activity vessels benefit from monthly checks during the peak season. To accommodate owners and guests, dockside areas with settees turn into a small oasis while teams work, with attractions nearby and a park across the harbor to stay engaged. Across the harbor, award-winning centers provide skilled techs and parts on demand.

Delivery and pricing: the plan uses a transparent approach, with available slots and variable pricing depending on parts and labor; price quotes are updated in real time and shared with owners. This plan is designed to accommodate owners and their guests. For families, kids and young crews, the schedule minimizes downtime and keeps a smooth flow across the marina.

Operations and safety: servicing tasks occur across the marina, with overhead lifts, hard stands and overhead access as needed; specialized teams handle rigging, electricity, and marine systems; outboards are lifted and serviced at dedicated bays; the entire plan aims to keep ideal operating windows for owners seeking quiet port calls and the best juice for crew.

Hull, Rigging and Mechanical Inspections: Checklist & Frequency

Begin with a formal, documented inspection of hull integrity, rigging condition and mechanical systems before any long voyage or seasonal use. Use a written checklist and store results in a service log to enable trend analysis over time.

Hull: assess gel-coat integrity and visible blistering, check fairing and fasteners, inspect keel bolts and straps, rudder stock wear, propeller shaft alignment and bearing play. Verify through-hulls and seacocks operate smoothly; test bilge pumps, high-water alarms and check the hull-to-deck joint for moisture. Inspect underwater fittings and corrosion protection, including anodes. Review paint or antifouling condition and note any delamination or cracking; document canvas covers for wear and UV damage. Record findings and plan replacement before the issue worsens.

Rigging: inspect wire rope for broken strands, corrosion and fraying; examine control lines for chafe and stiff spots. Check turnbuckles, chainplates, shackles and end fittings for elongation or corrosion; verify winches and clutches operate cleanly. Test fittings attachment points for movement or fatigue and confirm mounting hardware on the transom or mast is secure. If any doubt arises, replace suspect components and log the work for future reference, especially on lines and rigging hardware that see heavy use. Consider Edson helm components and fittings during replacement where applicable.

Mechanical: engine or outboard systems–check cooling water intake, hoses and clamps for leaks; inspect fuel lines, filters and tanks for contamination; test exhaust hoses and risers for signs of corrosion or cracking; review oil, lubrication and coolant levels; inspect belts, pulleys and impellers and verify alarm systems and gauges function. Perform a test run at idle and under load to ensure temperature, pressure and RPM readings align with manufacturer specifications. Use recommended tools and gauges; where possible, log readings alongside OEM service intervals. For steering and control, verify responsiveness and hydraulics if installed; Edson gear should be checked for smooth operation and secure mounting.

Frequency and scheduling: aim for hull and through-hull checks annually, with a mid-season inspection if operating in warm or high-salt conditions. Rigging inspections should occur every 12–18 months or sooner after a heavy load, collision or grounding. Mechanical systems should be evaluated every 6–12 months, or after any major maintenance event or noticeable performance change. Before any extended voyage, perform a pre-use check within 1–2 weeks and arrange a professional assessment after a docking or haul-out. In Portsmouth, waterfront marinas, coordinate with a local boatyard and, when needed, a renowned surveyor for formal certification.

Actions, record-keeping and sourcing: engage a trusted boatyard for lift-out access, parts replacement and alignment checks; leverage dealers for parts with potential discounts and faster availability. Maintain a single, centralized file that combines photos, measurements, part numbers and replacement dates; track items like zincs, hoses, seals and fittings on a rolling calendar. For affordable, repeatable upkeep, consider a canvas logbook and digital notes that can be shared with your team, ensuring the heart of your program remains in good condition. For preventive care, schedule a quarterly review that will help you avoid costly repairs and preserve the best performance of your vessel’s hull, rigging and mechanical systems. The process is widely trusted by professionals near the waterfront and across notable ports like Portsmouth, where Edson recommendations and durable, proven parts are readily available, and the overall care is renowned for its reliability and value. They will combine practical checks with strategic replacements to deliver steady, low-risk operation–and coffee breaks during long diagnostic sessions can help keep focus on the line and ensure you stay on track that day. Best practices: start early, document everything, and stay proactive rather than reactive.

Refit Planning: Scope, Budget, and Phasing for Portsmouth Projects

Begin with a 4-week scoping sprint for Portsmouth projects, locking the scope and agreeing a cap on spend before any procurement from a single owner who will track progress weekly. Treat Phase 1 as hull, deck, and core systems; Phase 2 as carpentry, seating, and head fittings; Phase 3 as painting, finish detailing, and exterior cosmetics. A hard, written scope prevents drift and helps insurance2 riders align with reality. The plan will provide the right foundation for decisions and set expectations across americas-based teams.

In Portsmouth, begin with a clear hull inspection and deep structural check: frames, stringers, deck penetrations, and mounting points for stability. Inspect bilge and pump equipment (edson pumps and controls), electrical backbone, plumbing, and the outboard systems. For the interior, map carpentry work for seating areas, bulkheads, and cabinetry; determine whether to refinish or replace surfaces to preserve historical value. If options exist, a second set of eyes from a local dealership will verify components and support a targeted search for authentic parts.

Build a budget template with line items for hull repairs, deck hardware, rigging, propulsion, electrical, water systems, interior carpentry, seating, and finishes. Add a 15–25% contingency for hidden issues and a separate allowance to cover overages. Include insurance2 riders and a defined procurement plan with a rhode island dealership to secure genuine parts. Start with the right order of long-lead items, such as outboard engines, edson controls, and steering heads, and track lead times to avoid short windows of downtime. Maintain a strict cap to prevent over budget. If owners require, obtain written approvals.

Phasing should mirror port constraints and usage patterns: weeks 1–2 focus on hull, deck, and systems; weeks 3–4 bring in interior carpentry, seating, and head fittings; painting windows should align with dry, stable weather, and a clear workspace reduces dust. Maintain a headcount plan and safety schedule to keep kids away from heavy equipment. Use a pool-sized staging area for materials and a path that avoids congestion on the pier. When testing, whether you simulate steering checks (steer) or engine runs, perform in shallow water first and move to deeper tests to ensure maneuverability before final commissioning.

Establish a tight change-control log and review cost burn weekly. Lock a firm handover date and document approvals from the insurer, the port, and the owner. Create a vistas-focused dashboard that tracks completed, in-progress, and blocked tasks, and maintain a clear book of maintenance entries to support future planning. If owners require, obtain written approvals and align painting strategies with environmental standards while respecting historical values.

Americas-wide collaborating teams and helping partners accelerate decisions; establish a robust path for approvals and a process to discover options early for long-lead items. Source components from a rhode island dealership to minimize delays. Protect nature and nearby shores by arranging waste-stream separation and avoiding impact on beaches, while keeping the project on schedule. This section emphasizes efficient, space-saving solutions that work in tight quarters and during emergencies, such as quick access to the head and fuel systems.

Book milestones in the calendar, verify the plan with the owner, and store all photos and measurements for a comprehensive registry. Confirm the seating layout and head placement meet comfort and accessibility needs for long passages. Document the full scope, including the deep-dive tasks and second-phase refinements, so the next project can begin with clear guidance across americas markets.

Concierge Spares & On-site Support: Logistics, Parts Sourcing, and Crew Coordination

Begin with a 24/7 spare plan that captains and on-site specialists own, staging critical items at the boatyard along with a small hull-access door库存 for rapid removal. This ensures the line stays tight, the heart of the system remains intact, and downtime is minimized at sunset or during calm weather.

Logistics are mapped to reduce dock delays: secure parking permissions, fuel-card access, and a single point of contact who coordinates with crews, yard staff, and shoreside partners. Have a fixed hour window for pickups and deliveries to avoid conflicts with busy periods and to keep the workflow smooth along the quay.

Parts sourcing relies on a vetted catalog: Interlux coatings, Yamaha propulsion spares, and essential sensors. Validate part numbers against the hull line and historic hardware, then track lead times, price, and compatibility in a formal search log. Maintain a million-dollar contingency line to cover sudden needs without delaying the search.

Crew coordination centers on a shared calendar so captains, engineers, deckhands, and specialists stay aligned. Establish clear arrival times, access procedures for doors and compartments, and a simple call-out for backups when kids onboard or guests visit the line at boatyard locations. This keeps power systems and steering controls responsive while preserving a calm, productive atmosphere.

On-site support teams perform rapid hardware swaps, power checks, and communications readiness. Prepare remote diagnostics when possible and ensure the right tools arrive with the crew. The goal is a smooth handover from dockside to on-deck work so the hull remains pristine and operations stay reliable while you enjoy a seamless operation along the quay.

| Item | 리드 타임 | Source | 참고 |

|---|---|---|---|

| Critical hull sensors | 24–48 hours | Local partner | Verify compatibility with historic hull systems |

| Interlux coatings batch | 5–7 days | Approved distributor | Match existing color and cure requirements |

| 전기 하네스 | 3–5일 | 전문 벤더 | 방수 커넥터, 표준 길이 |

| 추진 장치 예비 부품 (Yamaha) | 2–4 days | OEM 네트워크 | OEM 승인 부품, 백업 임펠러 키트 보관 |

| 도어/해치 개스킷 | 1–2 days | 지역 공방 | 도어 액세스 및 보안에 적합한지 확인하십시오. |

| 연료 피팅 및 호스 | 2–3 days | 해양 용품 공급업체 | ABYC/ISO 표준 충족 여부 확인 및 호환성 점검 |

| 선체 장착 전자 장비 | 7–14일 | OEM 카탈로그 | 펌웨어 호환성 및 서지 보호 |

드라이 도크, 인증 및 현지 규정: 포츠머스 특정 준수 단계

권고 사항: 포츠머스 승인 드라이 도크 사용 기간을 최소 12주 전에 확정하고, 서류 작업이 원활하게 진행될 수 있도록 경로를 확보하며, 야드 관리자와의 불필요한 소통을 최소화하기 위해 단일 연락 담당자를 지정하십시오.

- 도킹 전, 선박 등록, 최종 검사, 현재 선급 증서, 보험, 안전 계획 등 서류를 준비하십시오. 이것이 규제 기관의 기대치와 일치하는지 확인하고, 마일스톤 기반 일정을 작성하십시오. 야드 팀과 계약자가 쉽게 접근할 수 있도록 준비하고, 작업 시간을 최대화하기 위해 아침에 시작하고 진행 상황을 파악하기 위해 매일 밤 마무리하십시오.

- 항만 당국 및 현지 규정: 포츠머스 항만 관리소 또는 해양 사무소에 연락하여 선박 인양, 임시 계류 및 폐기물 처리에 대한 허가를 받으십시오. 소음, 조명 및 야간 작업에 대한 법규를 확인하고, 빌지 워터, 연료 잔여물 및 유압 오일에 대해서는 면허를 소지한 폐기물 처리 업체와 계약하십시오. 영수증을 보관하고 이웃 및 규제 기관에 보이는 로그를 유지하십시오. 이는 항구의 광채와 해안을 따라 서핑하는 사람들을 보호하는 데 도움이 됩니다.

- 인증 및 규정 준수: 선박 등급 상태 확인, 안전 장비, 소방 장비, 무전기 인증서 유효성 확인, 필요한 갱신은 미리 예약. 당국의 지침 출처를 활용하고 필요한 경우 마킹 업데이트. 이를 통해 앞으로 나아갈 방향을 자신 있게 생각할 수 있습니다.

- 환경 및 연료 취급: 유출 사고 대비 2차 방벽 설치, 유성 오수 분리 배출, 허가받은 폐기물 수거업체 이용. 폐기물 처리 영수증 기록, 야적장 및 주변에 공개된 폐기물 처리 일지 비치. 견고한 계획을 통해 경관을 보존하고 장시간 근무 중인 직원들을 위한 휴식 공간을 제공하여 정당한 신뢰를 얻을 수 있습니다.

- 야드 선정 및 가격 책정: 포츠머스 지역 시설 세 곳에서 인양, 도크 시설, 리프팅, 유틸리티, 현장 감독을 포함한 서면 견적을 요청하십시오. 가격을 투자 계획과 비교하고, 정시 완료에 대한 입증된 실적이 있는 야드를 선호하십시오. 두뇌를 맑게 유지하고 비용 절감을 달성할 수 있도록 전담 감독관을 요청하십시오. Hinckleys 고객의 경우 이는 종종 더 원활한 다중 서비스 거래로 이어집니다. 비상 사태에 대비하여 수백만 달러의 예산을 고려하십시오. 딜러십 네트워크를 통해 부품 및 장비를 확보할 수 있습니다.

- 도킹 중 운영 계획: 매일 아침 브리핑 및 다음 단계 초안을 매일 밤 작성; 간단한 뱅킹을 통해 추가 비용에 대한 자금 접근 보장; 현장 하우스 팀과 협력; 예비 부품 풀을 현장에 보관하고 승무원의 명확한 접근 유지; 이 접근 방식은 위험을 줄이고 하루 종일 프로젝트를 진행합니다.

- 도크 후 조치 및 기록 유지: 필요한 경우 해상 시운전을 실시하고, 최종 인증서를 취득하고 선박 파일에 규정 준수 출처를 업데이트합니다. 교체 부품이 문서화되었는지 확인하고 선체가 새롭게 빛나는지 확인합니다. 장비 구매를 위해 집이나 대리점으로 향하기 전에 내년 일정을 확인하십시오. 이를 통해 성능을 유지하고 여러 시즌에 걸쳐 투자를 보존하는 데 도움이 됩니다.

Hinckley Yacht Services – Premium Yacht Maintenance, Refits & Concierge Care">

Hinckley Yacht Services – Premium Yacht Maintenance, Refits & Concierge Care">