Choose a full-displacement Feadship 75m Arrow with hybrid propulsion to reduce vibrations and operate quietly at night, and specify a modular crew layout for efficient production and maintenance without downtime.

The design team, led by James Hopman, collaborates with hopman studios and blends Feadship’s craftsmanship with vitruvius-inspired proportioning, yielding generous volume amidships while keeping weight in check for the lower deck systems. The team focuses on aera-level comfort and clean exterior lines that reduce drag and enhance stability when underway.

Accommodates up to 12 guests in six suites, with refrigerated beverage storage and chilled galley provisions. The vessel geometry supports a low righting moment for smooth seas, while the lower guest deck minimizes movement in heavy seas. For the buyer, load planning embraces standard provisions and vessels operations.

The Arrow concept emphasizes a swift sale process for discerning buyers, offering transparent specifications and clear options with a dedicated team to tailor interior schemes. The on-board refrigeration, climate control, and cargo-carrying spaces are sized to support refrigerated provisions in extended voyages and cargo-days; this helps protect perishables across long itineraries. The production schedule aligns with Feadship’s standards, ensuring feasibility from hull construction to superstructure finishing. Input from james engineering reviews keeps the plan grounded in practical build realities.

The interior program relies on collaborations with tyba 그리고 aera for material palettes, with studies by tyba ensuring light-filled spaces that still maintain privacy. The hull form supports low fuel burn, while the lower deck amenities include a large gym, spa, and a refrigerated wine cellar. The sale-ready specification package helps a buyer evaluate progress across production milestones and keep the project on track.

For owners seeking timeless elegance and robust performance, Arrow will deliver a balanced combination of refined spaces and reliable systems, with a team focused on comfort, privacy, and operational clarity on long voyages.

Feadship 75m Arrow: Ultra-Luxury Superyacht Design & Specifications; Vitruvius

Recommendation: Choose Feadship 75m Arrow as the luxury on the ocean benchmark; its engineering delivers a stunning experience, with curves along the hull and expansive spaces that heighten the connection between guests and crew, placing it among the largest gigayachts in its class, all while offering smooth voyages without compromise.

Vitruvius-inspired proportions guide the Arrow’s design, with this balanced approach shaping headroom, hull stiffness, and deck layouts that provide cinema-grade sightlines and generous spaces along the main and upper decks. The result is a calm ride and curves that flow along the hull, turning technology into sculpture.

Engineering highlights include hydraulic stabilizers, a regulated power system, and a diesel-electric backbone tuned for long ocean passages. The propulsion, ballast, and deck machinery integrate with evrima interfaces and tyba controls, providing intuitive operation for captains and crew in any sea state.

Interiors center on spaces for dining and leisure, featuring a private cinema, tables for formal events, and coves along curved interiors that maximize natural light. Images from the added art program reveal meyer design cues and evrima textures, creating a seamless connection between technology and human comfort.

Operational notes emphasize the vessel’s registered status in the kingdom, with norway-based crews trained to operate the hydraulic and electrical systems. The head of engineering oversees added redundancies, and the companys network guarantees parts, service, and support across major ports, keeping the Arrow ready for first-class cruising with unmatched luxury.

Feadship 75m Arrow – Design Rationale, Build Specs, and Vitruvius Methodology

Suggested for the buyer: prioritize a flexible suites plan combined with a Vitruvius-based workflow and a robust hybrid propulsion core to ensure quiet operation, long range, and adaptable guest spaces.

Design Rationale

- The Arrow applies a streamlined hull form that minimizes wave impact while maximizing stability in winter sea states, keeping motion predictable for guests and crew alike.

- Interior planning centers on suites where owner and guests enjoy generous volume, paired with crew areas that maintain separation through dedicated corridors and captains boards for service coordination.

- Systems synapsis links propulsion, electrical, and navigation via a unified backbone, enabling real-time data sharing and simplified maintenance routines.

- Hybrid propulsion balances fuel efficiency with performance, allowing the vessel to run in pure electric mode at low speeds or in port, while maintaining engine redundancy for long crossings.

- Safety and detection networks weave through the vessel with fibre optic links, redundant sensors, and a centralized bridge that supports rapid decision-making.

Vitruvius Methodology

- Proportion and utility guide the layout, with a modular approach that preserves volume in the head compartments and service zones while keeping guest areas serene and secluded.

- Function follows form: every deck level supports a clear flow from fore to aft, minimizing cross-traffic and preserving quiet in the owner’s and guest suites.

- Material choice emphasizes longevity and lightness: steel hull for resilience, aluminium alloy superstructure for reduced weight aloft, and fibre-based composites where appropriate to balance rigidity and thermal performance.

- Systems integration adopts a single-point control strategy, where synapsis between engine, electrical plants, and hotel services improves reliability and maintenance cycles.

- Regulated safety layers are embedded at design time, aligning with international standards for vessels of this size while keeping crew access simple on every deck.

Build Specs

- Length overall: 75 m; beam and draft tuned for seakeeping and interior volume.

- Hull: steel; superstructure: aluminium; exterior finish designed to resist harsh climates and winter spray.

- Propulsion: hybrid system that combines diesel-electric drives with battery packs; on-demand electric cruising complements steady engine operation for long passages.

- Engine room layout emphasizes accessibility and safety, with paired generators and modular modules that simplify routine inspections and hot swaps.

- Fuel capacity and storage are managed with refrigerated provisions spaces and climate-controlled holds to preserve perishables during long legs at sea.

- Electrical backbone supports high-bandwidth fibre networks and real-time data for navigation, steering, and guest amenities.

- Navigation & bridge: Anschütz-based bridge with integrated navtex and starboard-aligned display arrays; head-up systems aid captain decisions in rough seas.

- Detection and safety: radar, AIS, and CCTV are wired through a central, fault-tolerant network; RH12 beacons provide robust distress signaling and redundancy.

- Deck equipment and tender handling: a balanced array of cranes and launches designed for operations in varied harbor environments and rough water.

- Interiors: suites configured for owner, guests, and crew with flexible partitions to adjust privacy levels; portable furniture options allow rapid reconfiguration if a buyer requires a different mix.

- Maintenance philosophy centers on modular components and common spare parts–marioff-based fire suppression, robust seals, and accessible service corridors maintain uptime across voyages.

Systems and Comfort Features

- Cooling and refrigeration systems support long passages with refrigerated stores that keep perishables optimal for extended charters.

- Communications rely on fibre optics, wired networks, and rapid detection routines to support crew and guest connectivity across all decks.

- Public areas on main and upper decks emphasize light-filled lounges and a star-inspired spatial rhythm that reinforces calm movement through spaces.

- Head compartments and en-suite facilities on guest decks feature high-water resistance and easy cleaning regimes for high-traffic events.

- Portable power solutions and quick-connect utilities allow on-tide maintenance without dockside downtime, helping the ship maintain a tight schedule.

- Winter readiness includes reinforced HVAC and insulation strategies to sustain comfort in colder climates during charters or crossings.

Operational Narrative

- The design supports multi-crew operation with clear workflows from the captain’s chairs to the engine room and discovery stations on the boards that guide daily routines.

- Starboard and port configurations align with safety margins and quick access routes for guests and crew, while the bridge crew relies on navtex and RH12 alerts for weather and operational advisories.

- The vessel’s making process centers on precise tolerances and controlled testing, ensuring that the final build aligns with Vitruvius-influenced metrics for balance and beauty without compromising function.

- Although the Arrow emphasizes elegance, it remains a capable platform for long voyages, with a disciplined approach to fuel efficiency, system redundancy, and onboard amenities.

Hull Form, Stability, and Seakeeping Strategy

Adopt a long, slender displacement hull with a soft entry and moderate beam. This nautical approach minimizes wave-making resistance at cruising speeds and cushions pitch in head seas, while carbon fiber hull panels and a lightweight, high-stiffness structure keep main weight low. feadships arrow concept uses a hull form refined through model tests and CFD, tuned to keep accelerations in staterooms and public areas comfortable across typical sea states. The editorial brief calls for predictable, calm motion rather than dramatic responses.

Stability strategy centers on a well-balanced weight plan and a ballast system that preserves a stable metacentric height (GM) across load cases. Target GM sits in the mid-range for a 75 m vessel, roughly 1.4 m, with ballast and trim-control tanks distributed along the midship sections to maximize righting moment. Heavy machinery, the main genset banks, and fuel tanks sit on both sides of the centerline to minimize heel sensitivity, while the deckhouse and sunreef lounge maintain even weight distribution. Electrical boards and the main switchboards are grouped to minimize vertical shifts and simplify emergency processing on the bridge. The builder team works with meyer and marioff to deliver a robust process, and alarms plus monitors provide continuous feedback in the engine room and on the bridge. The layout places the dumbwaiter near service points to support quiet, efficient meals without forcing crew to move heavy loads through guest spaces.

Seakeeping strategy blends active stabilization with refined hull shaping. The Arrow relies on fins and gyroscopic stabilization for zero-speed conditions, paired with a hull line that reduces pitch and squat in following seas. This approach keeps accelerations modest in staterooms and public areas, and is tracked by monitors that alert crew to any deviation in trim or roll. The saab-based navigation and radar suite integrates with the aera-control system to maintain stable trim and roll across seas, while decisions about line-of-sight and interior warmth echo spielberg-inspired attention to comfort and storytelling in the cabin feel. Guests sense a controlled, editorial ride at sea, with every motion contributing to a being aboard a well-built feadships ship.

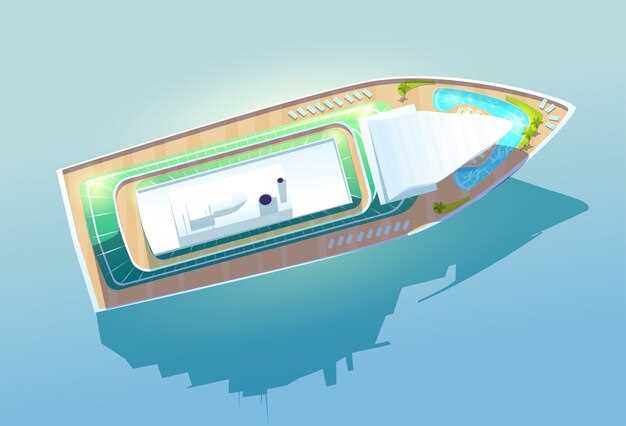

Deck Configurations: Outdoor Living, Helipad, and Tender Gallery

Opt for a full-beam outdoor living configuration with a fold-out dining zone and a dedicated tender gallery that keeps guests flowing from deck to water level. This setup anchors social moments on the main terrace while preserving clean sightlines along the hull’s square profile. Feadships ethos and lurssen-grade structural discipline inform the choice, with elevated, stylish seating and platforms that fold and reconfigure for winter gatherings or sun-soaked days.

Outdoor living zones should include a shaded lounge, a dining area, and a beach-lounging strip along the beam. Design emphasizes luminosity through large glazing, full-height windows, and carefully placed lighting that transitions from day to night. A refrigerated, portable bar station serves guests on demand, while a retractable shade system keeps the space comfortable in all seasons. Plan for easy access to the water and a near-seamless flow to the beach area, so guests can switch from conversation to dip in moments. Finch-inspired pendants add warmth to the luminosity without compromising visibility. Each guest enjoys unobstructed sightlines and close access to service pockets.

For the helipad, position it where the director can oversee operations from the bridge deck with clear sightlines to the approach path. Use a robust, load-tested platform, a retractable canopy, and a dedicated beaming system to guide arrivals. Equip with an elevator transfer for crew and guests, a weather beacon, and a dedicated safety margin that remains usable in winter winds. Ensure the surface is non-slip and finished with a climate-controlled, durable coating that resists salt spray. Systems integrate to coordinate wind alerts and power supply for winter launches.

The tender gallery should be roomy and adaptable, hosted on a square footprint with a high ceiling and multiple access points. A dedicated evrima platform and a pair of lifts allow launch and retrieval of a variety of tenders and toys. Include a refrigerated locker for equipment, a portable crane, and retractable side doors that shield storage when not in use. Palumbo principles guide ergonomics across the platform and cerri-grade fittings ensure precise alignment with the main deck’s beam, keeping a star area for a host console and direct access to the beach deck.

Each model option delivers specific configurations, and the buyer can tailor them to mission profiles. This deck trio–outdoor living, helipad, and tender gallery–shares consistent finish materials, cabin-grade lighting, and a unified control systems suite that coordinates climate, lighting, and safety features across platforms. The approach uses modular, weather-resistant furniture that can be reconfigured, with portable refrigeration and elevator transfers. A dedicated director can oversee operations, ensuring that each guest experiences roomy spaces and smooth transitions between zones.

Interior Architecture: Proportions, Materials, and Ambient Systems

Position the owner suite on the upper deck with directly connected access to a private terrace, a spacious 70–90 m2 cabin, and a bathroom with a dual-head arrangement that keeps daily routines quiet and private.

Proportions follow a Vitruvius-inspired logic: allocate about 40% of the main interior to public salons and dining, 28–32% to the owner’s suite and private cabins, 20–25% to guest cabins, and 8–12% to crew quarters. This distribution supports comfortable circulation through the vessel while maintaining abundant sightlines and natural cross-ventilation, making every space easy to navigate while enhancing serenity.

Materials favor warmth and tactility: walnut or oak veneers for cabinetry, limestone or marble for floors and baths, and expansive glass walls that visually extend the interior to the sea. The design draws on antonini and gruppo archives to shape seating geometry and casework, while lurssen joinery informs precision and durability. Introduce speck textures in textiles and subtle rug details, and apply heat-resistant finishes on high-use surfaces to ensure long-term performance through the maiden years and beyond.

Ambient systems tie comfort to reliability: layered lighting shifts from daylight to warm evening tones, acoustics tuned with perforated wood and fabric panels, and HVAC zones that keep upper decks cooler in hot climates. The gmdss suite sits in a protected area, navali sensors monitor hull and structure, and a hybrid energy loop supports smooth operation during tenders load and heavy sea states. Through smart controls, bathrooms stay dry, glass remains lightly diffused, and vessels aboard experience consistent climate control even when the range of activities expands.

The decor narrative echoes vitruvius principles of proportion and clarity, while the eagle-inspired exterior silhouette informs interior grain, hardware, and alignment. The owner’s favoured fabulous yet restrained décor blends lurssen heritage with the Italian craft voice from antonini and gruppo, shaping a prince-level environment suitable for both private moments and social gatherings. The maiden christened Arrow invites refinement during soon-following updates, directly aligning surfaces, colors, and textures with the term of elegance the owner seeks, making the space feel spacious and welcoming for every guest. This approach supports a design language that suits the prince or prominent guest alike, while remaining flexible for future changes on other vessels and in future refits, ensuring the interior remains cohesive across the fleet of vessels.

| Area / System | Material / Specification | Ambient Goal / Notes |

|---|---|---|

| Master suite (upper deck) | 70–90 m2 cabin; walnut veneer cabinetry; limestone shower; expansive glass walls; dual-head bathroom | Private, calm, with direct terrace access; high daylight control; robust joinery for long-term use |

| Public salons & dining | Calibrated glass walls; terrazzo or limestone floors; soft fabric panels | Spacious social zones with clear sightlines through to exterior decks |

| Crew & service areas | hard-wearing laminates; anti-slip surfaces; compact storage | Efficient circulation; minimized noise transfer to guest spaces |

| Bathing & heads | Ceramic/porcelain surfaces; non-slip textures; heat-resistant finishes | Low maintenance; durable in daily use on long passages |

| Lighting & acoustics | Layered LED systems; acoustic panels; mute metals | Natural daytime brightness with intimate evening ambience |

| Tenders & deck storage | Protected bays; glass doors; speck texture accents | Easy access and controlled ventilation when tenders are docked |

| 시스템 및 제어 | HVAC 구역 분할 (상단, 본체, 승무원); gmdss; navali 센서 | 균형 잡힌 열 부하; 안정적인 통신; 선체 건강 모니터링 |

추진력, 동력, 그리고 성능 벤치마크

디젤-전기 추진 패키지(두 개의 아지무스 러스터 및 보우 러스터 장착)를 설치하고, 모듈식 발전기 어레이로 구동합니다. Veit Studio는 레이아웃을 안내하며, 파워트레인을 상부 구조 내부에 두고 하부 갑판 바로 위에 배치하여 선장실과 손님 통로의 진동을 최소화합니다. 이러한 배치는 조용한 운항을 제공합니다. 12–14 knots 그리고 좁은 항구에서 정확하고 정밀한 조작.

성능 목표에는 최고 속도가 포함됩니다. 16.5–17.0 노트, 순항 중 12.5–14.0 노트, 그리고 설계 내구성이 6,500–7,000 nm 시속 12노트입니다. 디젤 전기 패키지는 급격한 바람에도 빠른 대응력을 유지하며, 능동형 안정화 및 효율적인 추진력을 통해 순항 속도에서 연료 소비를 약 25%만큼 줄일 수 있습니다.

엔지니어링 백본은 선박 전체 데이터용 섬유선 네트워크를 사용하며, 브리지와 엔진룸에서 실시간 모니터링을 가능하게 합니다. 두 개의 디젤 엔진은 두 개의 아지мут 추진기를 구동하며, 호텔 부하를 위한 전용 서비스 발전기 세트가 보완됩니다. 전용 압축기 루프는 에어컨 및 갤리 서비스를 처리하며, 해양용 식기세척기를 포함합니다. 생산 중 또는 수명 연장 업데이트 동안 업그레이드를 단순화하기 위해 레이아웃은 모듈식으로 유지되므로, 판매 또는 개조 계획은 가동 중단 없이 성능을 유지할 수 있습니다. 웨이크보드는 빠른 배치를 위해 선미 로커에 보관됩니다.

내부 인테리어에서는 팔룸보 데코가 단잔테 글레이징 및 론달 하드웨어와 조화를 이루어 상부 구조 전체에 세련된 색상 팔레트를 만들어냅니다. 마스터 스위트 포함 8개의 스위트는 손님들에게 프라이버시와 다양성을 제공합니다. 스필버그를 연상시키는 조명과 제어 그래픽은 선장과 승무원들을 위한 운영을 직관적으로 유지합니다. 생활 공간의 왕국은 따뜻한 목재, 섬유 악센트, 그리고 영리한 수납을 강조하며, 사려 깊은 서비스 구역과 전담 헬스장은 해상에서의 일상생활을 향상시킵니다.

유지 보수 및 업그레이드를 위해 생산 일정은 여전히 긴밀하며, 팀은 다음과 같은 응답을 할 수 있습니다. request 건축 중 또는 인도 후 변경 사항에 대비합니다. 선박 판매는 모듈식 개조와 일치할 수 있으며, Palumbo의 네트워크는 Rondal, Danzante 및 기타 파트너와 협력하여 최적의 성능을 유지합니다. 하부 갑판 배열은 서비스 접근성을 단순화하여 가장 중요할 때 임무 관련 시스템이 온라인 상태를 유지하도록 보장합니다.

지속 가능성, 자재 조달, 그리고 건설 기술

중앙부 선체 단면과 상부 구조물을 모듈화되고, 공장 밖에서 조립하여 시작하여, 사전 제작된 모듈을 사용하여 폐기물을 몇 퍼센트 줄이고 인도 시간을 단축합니다. 이러한 접근 방식은 설치 전체에 걸쳐 구조적 완전성을 유지하고, 일정 신뢰성의 선두 주자를 가능하게 하며, 시작부터 조선소를 효율적으로 유지합니다. 각 모듈은 정밀하게 가공되어 정렬된 다음, 현장에서 결합하여 극지 조건을 견딜 수 있는 선체와 안정적인 중앙부 스파인을 형성합니다.

자재 소싱은 인증된 목재 및 금속을 중심으로 이루어집니다: 실내 장식용 FSC 인증 목재, 프레임용 재활용 알루미늄, 창문용 재활용 유리입니다. 인디고 색상의 유리는 조명과 태양 제어를 최적화하는 반면, 저 VOC, 수성 마감재는 작업자와 환경을 보호합니다. 공급망 통제는 원산지를 공장까지 추적하여 자재의 출처를 보장합니다. 투명성에 대한 편집적 강조는 공급업체가 캡처한 탑승 이미지를 통해 드러나며, 소니 등급 카메라가 모든 세부 사항을 기록합니다.

시공 기술은 디지털 설계와 디지털 트윈을 활용하여 절단 전에 적합성을 검증합니다. 선미부 섹션, 선체 블록, 내장 파드가 사전 제작되어 현장에 배송되며, 로봇 용접과 정밀 고정 장치를 통해 깨끗한 접합부와 견고한 성능을 보장합니다. 상부 구조물은 무게 경로 분석을 통해 조종 센터의 최적 위치를 유지하면서 조립됩니다. 각 인터페이스는 표준 커넥터를 사용하여 유지 보수를 가속화하며, 엘리베이터 코어 및 계단 타워는 최소한의 공간 페널티로 통합됩니다.

온보드 지속 가능성 기능에는 고효율 시스템과 세심하게 설계된 승무원 편의 시설이 포함됩니다. 식기세척기 및 소형 갤리 슬래쉬는 물 사용량을 줄이고, 자쿠지는 제한적이고 잘 단열된 편안함을 제공하며 열 회수를 통해 에너지 소비를 최소화합니다. 갑판 전체를 연결하는 갑판 엘리베이터는 소형 및 저전력으로 작동합니다. 헬리덱은 태양 캐노피 및 기상 등급 조명과 통합됩니다. 하이브리드 추진 또는 배터리 저장 개념은 항력을 줄이는 스마트 선체 코팅과 함께 제공됩니다. 유리 장식으로 밝고 조용한 선체는 남색 유리가 장거리 항해 동안 발광을 유지합니다. 보안 시스템은 발사 및 페리 운항 중에 보관된 예비 부품 및 중요한 자재를 보호합니다.

스티븐의 편집 노트는 배송 마일스톤과 계획된 발사 창을 강조하며, 진행 상황을 확인하기 위한 여러 단계의 검사가 진행될 예정입니다. 소니 카메라로 촬영한 이미지는 초기 선체 모듈부터 최종 슈퍼스트럭처 장착에 이르기까지 빌드 효율성에서 여러 가지 최초의 사례를 기록합니다. 팀은 모든 모듈에 대한 품질 검사를 보장하며, 조선소의 왕자가 주요 검토에서 감독 역할을 수행합니다. 시간 효율성을 위해 제안된 시퀀스는 프로젝트를 계획대로 진행하는 동시에 안전 및 보안 기준을 유지합니다.

Feadship 75m Arrow – Ultra-Luxury Superyacht Design & Specifications">

Feadship 75m Arrow – Ultra-Luxury Superyacht Design & Specifications">