Choose a full-displacement Feadship 75m Arrow with hybrid propulsion to reduce vibrations and operate quietly at night, and specify a modular crew layout for efficient production and maintenance without downtime.

The design team, led by James Hopman, collaborates with hopman studios and blends Feadship’s craftsmanship with vitruvius-inspired proportioning, yielding generous volume amidships while keeping weight in check for the lower deck systems. The team focuses on aera-level comfort and clean exterior lines that reduce drag and enhance stability when underway.

Accommodates up to 12 guests in six suites, with refrigerated beverage storage and chilled galley provisions. The vessel geometry supports a low righting moment for smooth seas, while the lower guest deck minimizes movement in heavy seas. For the buyer, load planning embraces standard provisions and vessels operations.

The Arrow concept emphasizes a swift sale process for discerning buyers, offering transparent specifications and clear options with a dedicated team to tailor interior schemes. The on-board refrigeration, climate control, and cargo-carrying spaces are sized to support refrigerated provisions in extended voyages and cargo-days; this helps protect perishables across long itineraries. The production schedule aligns with Feadship’s standards, ensuring feasibility from hull construction to superstructure finishing. Input from james engineering reviews keeps the plan grounded in practical build realities.

The interior program relies on collaborations with tyba そして aera for material palettes, with studies by tyba ensuring light-filled spaces that still maintain privacy. The hull form supports low fuel burn, while the lower deck amenities include a large gym, spa, and a refrigerated wine cellar. The sale-ready specification package helps a buyer evaluate progress across production milestones and keep the project on track.

For owners seeking timeless elegance and robust performance, Arrow will deliver a balanced combination of refined spaces and reliable systems, with a team focused on comfort, privacy, and operational clarity on long voyages.

Feadship 75m Arrow: Ultra-Luxury Superyacht Design & Specifications; Vitruvius

Recommendation: Choose Feadship 75m Arrow as the luxury on the ocean benchmark; its engineering delivers a stunning experience, with curves along the hull and expansive spaces that heighten the connection between guests and crew, placing it among the largest gigayachts in its class, all while offering smooth voyages without compromise.

Vitruvius-inspired proportions guide the Arrow’s design, with this balanced approach shaping headroom, hull stiffness, and deck layouts that provide cinema-grade sightlines and generous spaces along the main and upper decks. The result is a calm ride and curves that flow along the hull, turning technology into sculpture.

Engineering highlights include hydraulic stabilizers, a regulated power system, and a diesel-electric backbone tuned for long ocean passages. The propulsion, ballast, and deck machinery integrate with evrima interfaces and tyba controls, providing intuitive operation for captains and crew in any sea state.

Interiors center on spaces for dining and leisure, featuring a private cinema, tables for formal events, and coves along curved interiors that maximize natural light. Images from the added art program reveal meyer design cues and evrima textures, creating a seamless connection between technology and human comfort.

Operational notes emphasize the vessel’s registered status in the kingdom, with norway-based crews trained to operate the hydraulic and electrical systems. The head of engineering oversees added redundancies, and the companys network guarantees parts, service, and support across major ports, keeping the Arrow ready for first-class cruising with unmatched luxury.

Feadship 75m Arrow – Design Rationale, Build Specs, and Vitruvius Methodology

Suggested for the buyer: prioritize a flexible suites plan combined with a Vitruvius-based workflow and a robust hybrid propulsion core to ensure quiet operation, long range, and adaptable guest spaces.

Design Rationale

- The Arrow applies a streamlined hull form that minimizes wave impact while maximizing stability in winter sea states, keeping motion predictable for guests and crew alike.

- Interior planning centers on suites where owner and guests enjoy generous volume, paired with crew areas that maintain separation through dedicated corridors and captains boards for service coordination.

- Systems synapsis links propulsion, electrical, and navigation via a unified backbone, enabling real-time data sharing and simplified maintenance routines.

- Hybrid propulsion balances fuel efficiency with performance, allowing the vessel to run in pure electric mode at low speeds or in port, while maintaining engine redundancy for long crossings.

- Safety and detection networks weave through the vessel with fibre optic links, redundant sensors, and a centralized bridge that supports rapid decision-making.

Vitruvius Methodology

- Proportion and utility guide the layout, with a modular approach that preserves volume in the head compartments and service zones while keeping guest areas serene and secluded.

- Function follows form: every deck level supports a clear flow from fore to aft, minimizing cross-traffic and preserving quiet in the owner’s and guest suites.

- Material choice emphasizes longevity and lightness: steel hull for resilience, aluminium alloy superstructure for reduced weight aloft, and fibre-based composites where appropriate to balance rigidity and thermal performance.

- Systems integration adopts a single-point control strategy, where synapsis between engine, electrical plants, and hotel services improves reliability and maintenance cycles.

- Regulated safety layers are embedded at design time, aligning with international standards for vessels of this size while keeping crew access simple on every deck.

Build Specs

- Length overall: 75 m; beam and draft tuned for seakeeping and interior volume.

- Hull: steel; superstructure: aluminium; exterior finish designed to resist harsh climates and winter spray.

- Propulsion: hybrid system that combines diesel-electric drives with battery packs; on-demand electric cruising complements steady engine operation for long passages.

- Engine room layout emphasizes accessibility and safety, with paired generators and modular modules that simplify routine inspections and hot swaps.

- Fuel capacity and storage are managed with refrigerated provisions spaces and climate-controlled holds to preserve perishables during long legs at sea.

- Electrical backbone supports high-bandwidth fibre networks and real-time data for navigation, steering, and guest amenities.

- Navigation & bridge: Anschütz-based bridge with integrated navtex and starboard-aligned display arrays; head-up systems aid captain decisions in rough seas.

- Detection and safety: radar, AIS, and CCTV are wired through a central, fault-tolerant network; RH12 beacons provide robust distress signaling and redundancy.

- Deck equipment and tender handling: a balanced array of cranes and launches designed for operations in varied harbor environments and rough water.

- Interiors: suites configured for owner, guests, and crew with flexible partitions to adjust privacy levels; portable furniture options allow rapid reconfiguration if a buyer requires a different mix.

- Maintenance philosophy centers on modular components and common spare parts–marioff-based fire suppression, robust seals, and accessible service corridors maintain uptime across voyages.

Systems and Comfort Features

- Cooling and refrigeration systems support long passages with refrigerated stores that keep perishables optimal for extended charters.

- Communications rely on fibre optics, wired networks, and rapid detection routines to support crew and guest connectivity across all decks.

- Public areas on main and upper decks emphasize light-filled lounges and a star-inspired spatial rhythm that reinforces calm movement through spaces.

- Head compartments and en-suite facilities on guest decks feature high-water resistance and easy cleaning regimes for high-traffic events.

- Portable power solutions and quick-connect utilities allow on-tide maintenance without dockside downtime, helping the ship maintain a tight schedule.

- Winter readiness includes reinforced HVAC and insulation strategies to sustain comfort in colder climates during charters or crossings.

Operational Narrative

- The design supports multi-crew operation with clear workflows from the captain’s chairs to the engine room and discovery stations on the boards that guide daily routines.

- Starboard and port configurations align with safety margins and quick access routes for guests and crew, while the bridge crew relies on navtex and RH12 alerts for weather and operational advisories.

- The vessel’s making process centers on precise tolerances and controlled testing, ensuring that the final build aligns with Vitruvius-influenced metrics for balance and beauty without compromising function.

- Although the Arrow emphasizes elegance, it remains a capable platform for long voyages, with a disciplined approach to fuel efficiency, system redundancy, and onboard amenities.

Hull Form, Stability, and Seakeeping Strategy

Adopt a long, slender displacement hull with a soft entry and moderate beam. This nautical approach minimizes wave-making resistance at cruising speeds and cushions pitch in head seas, while carbon fiber hull panels and a lightweight, high-stiffness structure keep main weight low. feadships arrow concept uses a hull form refined through model tests and CFD, tuned to keep accelerations in staterooms and public areas comfortable across typical sea states. The editorial brief calls for predictable, calm motion rather than dramatic responses.

Stability strategy centers on a well-balanced weight plan and a ballast system that preserves a stable metacentric height (GM) across load cases. Target GM sits in the mid-range for a 75 m vessel, roughly 1.4 m, with ballast and trim-control tanks distributed along the midship sections to maximize righting moment. Heavy machinery, the main genset banks, and fuel tanks sit on both sides of the centerline to minimize heel sensitivity, while the deckhouse and sunreef lounge maintain even weight distribution. Electrical boards and the main switchboards are grouped to minimize vertical shifts and simplify emergency processing on the bridge. The builder team works with meyer and marioff to deliver a robust process, and alarms plus monitors provide continuous feedback in the engine room and on the bridge. The layout places the dumbwaiter near service points to support quiet, efficient meals without forcing crew to move heavy loads through guest spaces.

Seakeeping strategy blends active stabilization with refined hull shaping. The Arrow relies on fins and gyroscopic stabilization for zero-speed conditions, paired with a hull line that reduces pitch and squat in following seas. This approach keeps accelerations modest in staterooms and public areas, and is tracked by monitors that alert crew to any deviation in trim or roll. The saab-based navigation and radar suite integrates with the aera-control system to maintain stable trim and roll across seas, while decisions about line-of-sight and interior warmth echo spielberg-inspired attention to comfort and storytelling in the cabin feel. Guests sense a controlled, editorial ride at sea, with every motion contributing to a being aboard a well-built feadships ship.

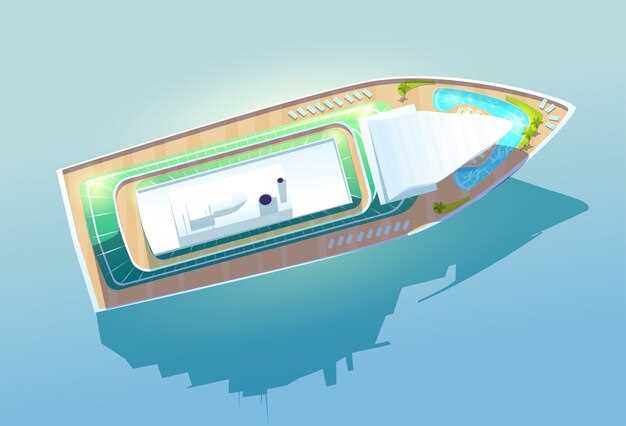

Deck Configurations: Outdoor Living, Helipad, and Tender Gallery

Opt for a full-beam outdoor living configuration with a fold-out dining zone and a dedicated tender gallery that keeps guests flowing from deck to water level. This setup anchors social moments on the main terrace while preserving clean sightlines along the hull’s square profile. Feadships ethos and lurssen-grade structural discipline inform the choice, with elevated, stylish seating and platforms that fold and reconfigure for winter gatherings or sun-soaked days.

Outdoor living zones should include a shaded lounge, a dining area, and a beach-lounging strip along the beam. Design emphasizes luminosity through large glazing, full-height windows, and carefully placed lighting that transitions from day to night. A refrigerated, portable bar station serves guests on demand, while a retractable shade system keeps the space comfortable in all seasons. Plan for easy access to the water and a near-seamless flow to the beach area, so guests can switch from conversation to dip in moments. Finch-inspired pendants add warmth to the luminosity without compromising visibility. Each guest enjoys unobstructed sightlines and close access to service pockets.

For the helipad, position it where the director can oversee operations from the bridge deck with clear sightlines to the approach path. Use a robust, load-tested platform, a retractable canopy, and a dedicated beaming system to guide arrivals. Equip with an elevator transfer for crew and guests, a weather beacon, and a dedicated safety margin that remains usable in winter winds. Ensure the surface is non-slip and finished with a climate-controlled, durable coating that resists salt spray. Systems integrate to coordinate wind alerts and power supply for winter launches.

The tender gallery should be roomy and adaptable, hosted on a square footprint with a high ceiling and multiple access points. A dedicated evrima platform and a pair of lifts allow launch and retrieval of a variety of tenders and toys. Include a refrigerated locker for equipment, a portable crane, and retractable side doors that shield storage when not in use. Palumbo principles guide ergonomics across the platform and cerri-grade fittings ensure precise alignment with the main deck’s beam, keeping a star area for a host console and direct access to the beach deck.

Each model option delivers specific configurations, and the buyer can tailor them to mission profiles. This deck trio–outdoor living, helipad, and tender gallery–shares consistent finish materials, cabin-grade lighting, and a unified control systems suite that coordinates climate, lighting, and safety features across platforms. The approach uses modular, weather-resistant furniture that can be reconfigured, with portable refrigeration and elevator transfers. A dedicated director can oversee operations, ensuring that each guest experiences roomy spaces and smooth transitions between zones.

Interior Architecture: Proportions, Materials, and Ambient Systems

Position the owner suite on the upper deck with directly connected access to a private terrace, a spacious 70–90 m2 cabin, and a bathroom with a dual-head arrangement that keeps daily routines quiet and private.

Proportions follow a Vitruvius-inspired logic: allocate about 40% of the main interior to public salons and dining, 28–32% to the owner’s suite and private cabins, 20–25% to guest cabins, and 8–12% to crew quarters. This distribution supports comfortable circulation through the vessel while maintaining abundant sightlines and natural cross-ventilation, making every space easy to navigate while enhancing serenity.

Materials favor warmth and tactility: walnut or oak veneers for cabinetry, limestone or marble for floors and baths, and expansive glass walls that visually extend the interior to the sea. The design draws on antonini and gruppo archives to shape seating geometry and casework, while lurssen joinery informs precision and durability. Introduce speck textures in textiles and subtle rug details, and apply heat-resistant finishes on high-use surfaces to ensure long-term performance through the maiden years and beyond.

Ambient systems tie comfort to reliability: layered lighting shifts from daylight to warm evening tones, acoustics tuned with perforated wood and fabric panels, and HVAC zones that keep upper decks cooler in hot climates. The gmdss suite sits in a protected area, navali sensors monitor hull and structure, and a hybrid energy loop supports smooth operation during tenders load and heavy sea states. Through smart controls, bathrooms stay dry, glass remains lightly diffused, and vessels aboard experience consistent climate control even when the range of activities expands.

The decor narrative echoes vitruvius principles of proportion and clarity, while the eagle-inspired exterior silhouette informs interior grain, hardware, and alignment. The owner’s favoured fabulous yet restrained décor blends lurssen heritage with the Italian craft voice from antonini and gruppo, shaping a prince-level environment suitable for both private moments and social gatherings. The maiden christened Arrow invites refinement during soon-following updates, directly aligning surfaces, colors, and textures with the term of elegance the owner seeks, making the space feel spacious and welcoming for every guest. This approach supports a design language that suits the prince or prominent guest alike, while remaining flexible for future changes on other vessels and in future refits, ensuring the interior remains cohesive across the fleet of vessels.

| Area / System | Material / Specification | Ambient Goal / Notes |

|---|---|---|

| Master suite (upper deck) | 70–90 m2 cabin; walnut veneer cabinetry; limestone shower; expansive glass walls; dual-head bathroom | Private, calm, with direct terrace access; high daylight control; robust joinery for long-term use |

| Public salons & dining | Calibrated glass walls; terrazzo or limestone floors; soft fabric panels | Spacious social zones with clear sightlines through to exterior decks |

| Crew & service areas | hard-wearing laminates; anti-slip surfaces; compact storage | Efficient circulation; minimized noise transfer to guest spaces |

| Bathing & heads | Ceramic/porcelain surfaces; non-slip textures; heat-resistant finishes | Low maintenance; durable in daily use on long passages |

| Lighting & acoustics | Layered LED systems; acoustic panels; mute metals | Natural daytime brightness with intimate evening ambience |

| Tenders & deck storage | Protected bays; glass doors; speck texture accents | 船舶が係留されている際の容易なアクセスと制御された換気 |

| Systems & control | HVACゾーニング(上、メイン、乗組員);GMDSS;navaliセンサー | バランスの取れた熱負荷; 信頼性の高い通信; ハル健康状態モニタリング |

Propulsion, Power, and Performance Benchmarks

ディーゼル電気推進パッケージを2つのアジマス推進器とバウ・スラスターを備えて搭載し、モジュール式発電機アレイで給電します。Veit Studioがレイアウトを指導し、パワートレインを上部構造内に配置し、船底のすぐ上に設置することで、船長の操舵室やゲストの回廊での振動を最小限に抑えます。この配置により、静かなモーター走行が可能になります。 12–14 knots そして、狭い港での正確な操縦。.

性能目標には最高速度が含まれます。 16.5–17.0 ノット, クルージングで 12.5–14.0 ノット, 、そして設計の耐久性を 6,500–7,000 nm 時速12ノットで航行。ディーゼル電気推進システムは、突風下でも迅速な対応を維持し、アクティブスタビライゼーションと効率的な推進力によって、巡航速度で燃料消費量を約25%削減できます。.

エンジニアリングのバックボーンは、船内全体のデータのために光ファイバー回線ネットワークを使用し、ブリッジやエンジンルームからのリアルタイム監視を可能にします。 2つのディーゼルエンジンが2つのアジマス推進器を動かし、ホテル負荷用の専用サービス発電機で補完されます。 専用コンプレッサーループは、空調や調理場サービスを処理し、船舶グレードの食洗機を含みます。 生産中または中間寿命の更新中のアップグレードを簡素化するために、レイアウトはモジュール式に保たれ、販売または改造計画がダウンタイムなしで性能を維持できるようにします。 ウェイクボードは、迅速な展開のためにトランクルームに保管されます。.

内部では、パルumboの内装が、danzanteのガラスとrondalのハードウェアと調和し、スーパー構造全体に洗練された配色を生み出しています。マスタースイートを含む8つのスイートルームは、ゲストにプライバシーと多様性を提供します。シュピーバーグ監督にインスパイアされた照明とコントロールグラフィックスにより、船長と乗組員にとって操作が直感的になります。生活空間の王国は、温かみのある木材、繊維のアクセント、そして巧妙な収納を強調し、配慮の行き届いたサービスエリアと専用ジムは、海での日々の生活を向上させます。.

メンテナンスやアップグレードのため、生産スケジュールは逼迫しており、チームは次の事態に対応できます。 request 建築中または納入後に行われる変更に対応できるように設計されています。船の売却は、モジュール型改造と連携し、PalumboのネットワークはRondal、Danzante、その他のパートナーと協力して最高のパフォーマンスを維持します。最下層のレイアウトはサービスアクセスを簡素化し、最も重要な時にミッションクリティカルなシステムが稼働し続けることを保証します。.

持続可能性、材料調達、および建設技術

船体の中央部セクションと上部構造をモジュール式、オフサイトで建設開始し、プレハブモジュールを使用することで、廃棄物を数パーセント削減し、納期を短縮します。このアプローチは、設置全体にわたる構造的完全性を維持し、スケジュール信頼性における初の試みを実現すると同時に、造船所を最初から効率的に維持できます。各モジュールは精密に加工され、現場で結合されて、極地対応型の船体と安定した船体中央部の背骨を形成します。.

材料調達は、認証された木材と金属を中心にしています。内装にはFSC認証の木材、フレームにはリサイクルアルミニウム、窓にはリサイクルガラスを使用します。インディゴ染めのガラスは、輝度と太陽光コントロールを最適化し、低VOC、水性塗料は、作業員と環境を保護します。サプライチェーン管理は、材料の原産地を製材所までトレーサビリティし、材料の来歴を保証します。透明性への編集上の重点は、サプライヤーが撮影したオンボード画像に明らかであり、sony製のカメラで細部をすべて記録しています。.

建設技術は、切断前に適合性を検証するためにデジタル設計とデジタルツインを活用します。プレハブされた中央部セクション、船殻ブロック、および内部ポッドが現場に輸送されます。ロボット溶接と精密な固定により、クリーンな接合部と堅牢な性能を確保します。スーパー構造は、重心を最適に保つために、荷重パス分析を用いて組み立てられます。各インターフェースは、標準化されたコネクタを使用してメンテナンスを加速させ、エレベーターシャフトコアと階段タワーは、最小限のスペースペナルティで統合されます。.

オンボードのサステナビリティ機能には、高効率システムと、細部まで配慮された乗組員向けアメニティが含まれます。食洗機とコンパクトなギャレーは水の使用量を削減し、ジャグジーは限られた範囲で、断熱性に優れ、ヒートリサイクルによってエネルギー消費を最小限に抑えた快適性を提供します。オンボードエレベーターは、コンパクトで低エネルギーの動作で全甲板を接続します。ヘリパッドは、ソーラーキャノピーと耐候性照明と統合されています。ハイブリッド推進またはバッテリーストレージのコンセプトは、ドラッグを低減するスマートハルコーティングと並んでいます。ガラスアクセントを施した船体は、インディゴガラスが長期間の航海中に発光を維持することで、明るく静かさを保ちます。セキュリティシステムは、打ち上げやフェリー輸送中に保管されているスペアパーツや重要な材料を保護します。.

スティーブンの編集ノートは、納入マイルストーンと計画された打ち上げウィンドウについて強調しており、進捗状況を確認するための段階的な検査がいくつか含まれています。sonyカメラで撮影された画像は、初期の船体モジュールから最終的なスーパー構造物の適合に至るまで、構築効率におけるいくつかの第一を示すものを文書化しています。チームは、品質チェックがすべてのモジュールをカバーしていることを保証し、造船所のプリンスが重要なレビューで監督を行います。時間効率のために、提案されたシーケンスは、安全およびセキュリティ基準を維持しながら、プロジェクトを順調に進めます。.

Feadship 75m Arrow – Ultra-Luxury Superyacht Design & Specifications">

Feadship 75m Arrow – Ultra-Luxury Superyacht Design & Specifications">