Recommendation: choose the suprema profile as the standard general arrangement for Adler Yacht. It allows efficient weight distribution, straightforward maintenance access, and a clean interaction between living areas and sea-keeping requirements. This layout already has an awarded pedigree for precision and consistency.

It centers on πέντε zones–bridge, main salon, galley, guest accommodations, and the engine room–creating a clear combination of public and private spaces. Screened bulkheads and kevlar-reinforced panels shield critical equipment while keeping pathways unobstructed.

The layout supports long voyages with optimized fuel placement, reducing refueling hours and enabling 18–24 hours of continuous operation on typical routes. Tanks balance trim and CG, while service corridors stay aligned with living spaces for quick checks during surveys.

For owners evaluating options, the suprema plan makes it easy to compare against other layouts. It offers a flat deck flow, clear sightlines, and a screen strategy that hides maintenance tasks while keeping everything you need at a glance. This approach will stir interest among yards and crews for its practical, modular makeup.

In an industry that values reliable profiles and proven standards, this general arrangement supports quick procurement, predictable build costs, and πέντε focused upgrade paths–from hull reinforcements to interior screens–without disrupting the core layout.

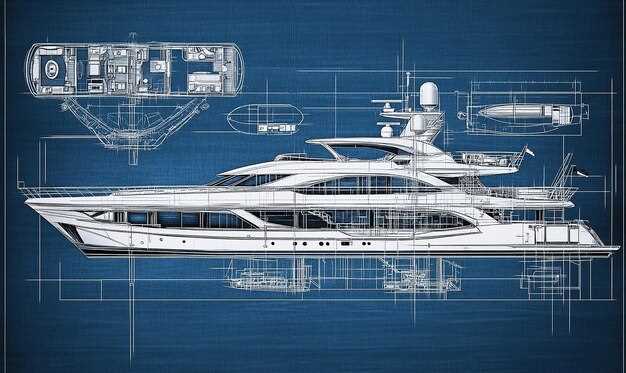

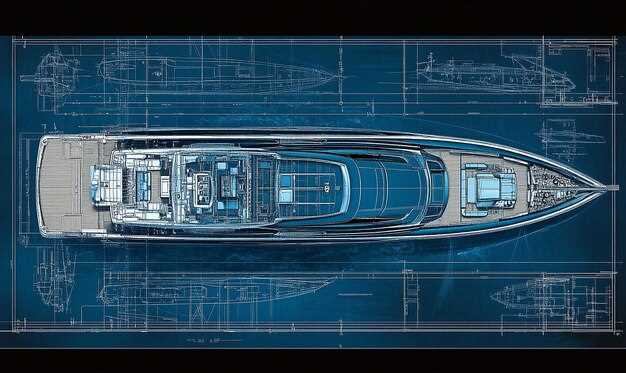

ADLER SUPREMA Yacht General Arrangement Plans

If youre planning a charter, begin with a precise deck plan that prioritizes guest comfort and crew efficiency. Align lounges, dining, and the helm on the main deck to support easy circulation, with a protected aft terrace for social life. Decide the number of cabins based on your needs; six to eight guest cabins plus a full crew area is common, but adjust as required. Position the galley and mess for rapid service while keeping disturbances away from sleeping zones. Ensure the tender garage and stern access allow direct operation of water toys and provision flows.

Safety and systems come first: map fire suppression zones, ballast and stability elements, and redundant propulsion controls into a protected core. Use double redundant power paths and an emergency generator to minimize downtime. Integrate infrared sensors for perimeter monitoring and crew safety, particularly on the stern and bow decks. The whole core houses critical equipment, with clean maintenance routes that avoid guest spaces.

Style and inspiration: ADLER SUPREMA reflects italy design language, with strong italian solutions shaping the interiors and exterior. Italy influences interior finishes, with warm materials, clean lines, and smart storage. The suprema approach keeps the exterior silhouette elegant while prioritizing usable space and light. Materials used in the interiors emphasize durability and easy maintenance.

Technology and features: the GA centers on innovation with modular systems and high-capacity services. The layout gathers features from the gmbh engineering network, enabling standard upgrades. A single bridge console ties navigation, propulsion, climate, and entertainment into one interface. Infrared cameras and sensors augment safety around access points, while redundancy across power and data networks supports continuous operation.

Take these steps when reviewing the GA: verify number of guest and crew berths, confirm safety equipment placements, check engine room access and ventilation, and validate tender allocation. Confirm that the storage and crew areas match operational needs; ensure the layout leaves room for future upgrades in power or data systems. With a clear GA, you gain a cohesive feeling of quality and reliability across the full length of the yacht.

Adler Suprema Hybrid: Design, Layout, and Technical Overview

Opt for the Adler Suprema Hybrid propulsion package as the baseline for efficient cruising and quiet operation. The system blends electric drive with a compact auxiliary unit to deliver smooth maneuvering and long-range capability.

Layout places energy packs and inverters in a dedicated machinery space aft. Modular battery packs are distributed along the lower deck to minimize vibration and to simplify cooling routing, while keeping service access straightforward.

Electrical architecture centers on a 400 V DC bus feeding two electric drives up to 250 kW each, with a compact genset tasked to extend range during high-load passages. A dedicated energy management unit coordinates charging, discharging, and shore-power when connected.

Interior spaces feature warm finishes and opaque screens to manage light, while large displays on the bridge and living areas present key data about power flow, battery status, and propulsion mode.

Thermal management relies on water-based cooling loops and suppression of vibrations through isolation and dampers. Battery packs use a mix of passive cooling and, where needed, active cooling in sealed modules to keep performance steady under heavy load.

The internet explains how a modular energy system lowers noise and fuel use in day-to-day operation, with the ability to maintain a steady cruise profile across sea conditions. Yachts benefit from predictable draw and comfortable ambient levels in the cabins.

For operators, the layout keeps service access clear in the aft spaces and on the bridge, supporting quick checks and rapid component swaps. Screens and dashboards make it easy to monitor battery packs, propulsion, and energy metrics from the helm and from crew areas.

Deck Layout: Fore, Midship, and Aft Zones

Implement a fixed fore-midship-aft zoning layout as the baseline for this vessel, then test it on deck for flow and security before final production.

Fore Zone. Allocate 20–25% of deck area to forward operations, including mooring gear, anchor handling, and a secure access point to the bow lounge. Place two windows on the fore cabin for natural light and visibility, and install a weather screen to reduce spray in rough seas. Use a dedicated crew passage with a lockable hatch to keep the guest areas quiet, ensuring a quick response from the team during lines handling. Example: a 60 m class yacht can fit a compact fore deck of roughly 180–240 m2, enabling efficient tasking while maintaining full security for aboard guests.

Midship Zone. This is the core living and service hub. Reserve the majority of deck space here (about 60–65%), hosting the main salon, dining area, galley, wheelhouse, and the primary circulation spine. Large panoramic windows or a screen wall along the hull enhance enjoying sea views from the main deck. Plan the diesel-electric power and control systems near this zone to reduce vibration transfer to guest spaces, improving comfort for years aboard. Maintain generous headroom and a clear, direct path from the main entrance to both guest areas and crew routines, supporting a modern, high-quality experience for every voyage. philipp, part of the shipyard development team, says this layout helps market-ready yachts meet growing owner expectations while keeping the team focused on security and service performance.

Aft Zone. Reserve 15–20% of deck area for the tender garage, beach club, and outdoor living space. Ensure robust access from the midship zone to aft terraces, with a covered area that extends the usable space for dining and lounging. Install a pair of secure exits to the crew mess and service corridors, and place storage for water toys and diving gear close to the stern. Aft deck planning should minimize engine noise intrusion into guest zones, aligning with a diesel-electric layout in which the generator room sits near the stern to reduce vibration. This zone completes the aboard experience, enabling easy deployment of tenders and outdoor activities while supporting security and operational efficiency for the shipyard and market.

Development notes: this approach supports a full operational tempo while maintaining a calm, onboard ambiance. The distribution aligns with modern yacht GA plans used in the Adler Suprema projects and is designed to be scalable for different years and hull sizes. Example configurations can be adjusted for different team sizes or owner preferences, with the shipyard providing support to ensure crew safety and guest comfort. Windows και screen placements are optimized to balance sightlines and glare control, helping security and crowd management aboard.

This zoning enables efficient workflow, as the team can operate in dedicated zones without crossing guest areas repeatedly, and it supports a smooth transition from mooring to sea trials. Market feedback across σκάφη αναψυχής of similar scale shows owners value a clear fore, mid, and aft separation for operations, service, and outdoor life, with security and comfort as top priorities. Part of the Adler Suprema philosophy is to deliver a robust, modern deck plan that can be tailored for different companies and owner needs, while staying aboard a vessel designed for long-term enjoyment by crews and guests alike.

Interior Configuration: Saloon, Cabins, and Service Areas

Start with a modular, hybrid saloon layout that blends modern comfort with practical control and glass vistas, ensuring your guests feel welcome from the first moment.

Let the saloon anchor the flow of the yacht: a warm, flexible space that can be reconfigured for dining, games, or quiet conversation while maintaining clear sightlines to the helm and galley. Use a simple, durable palette that supports long days at sea and testing of seating arrangements to confirm comfort and usability.

- Saloon arrangement

- Seating: a deep L-shaped sofa paired with two movable armchairs; cushions with removable covers; under-seat storage to reduce clutter; including a compact coffee table that can be swapped for a larger dining pedestal when needed.

- Dining and social zone: extendable table on a low-profile base; maintain at least 1.2 m of free circulation around the table for easy movement between seats.

- Glass and sightlines: panoramic, frameless glass windows along the sides; optional glass partition to the galley that preserves openness while reducing glare.

- Control and automation: integrated control panel in the saloon cabinetry; wireless handsets for lighting, climate, and media; ensure reach from seating plus a secondary panel near the helm for quick adjustments.

- Cabins

- Bed configurations: king bed around 1.8 m wide or two twins about 0.9 m each; provide 0.5–0.6 m of clearance beside the beds; optimize under-bed storage and a dedicated wardrobe for a clean footprint.

- Privacy and acoustics: private en-suite heads in the master cabin; acoustic insulation between cabins and corridor to support a quiet level of rest.

- Lighting and climate: warm reading lights at each berth; independent climate control per cabin; use glass panels or light-transmitting partitions to enhance daylight without compromising privacy.

- Finishes and testing: select materials with low maintenance and proven durability; test layouts with a small crew group (6–8) to validate cleaning efficiency and everyday use.

- Service areas

- Galley: compact but efficient, with a straight or L-shaped work zone; direct pass-through to the saloon; include an ice maker, wine storage, and a high-capacity extraction hood; use glass-front cabinetry to showcase hygiene and simplify cleaning.

- Crew area and mess: functional crew cabin with shared head; separate mess with durable seating; robust ventilation and sound isolation from guest spaces.

- Utility and systems: service corridor between galley and engine room; accessible panels and ladder access; water maker, battery monitoring, and storage placed for quick access during operations.

- Finish and controls: corrosion-resistant hardware; low-noise pumps and compressors; glass splashbacks in the galley for hygiene and ease of maintenance.

For the market and branding, the supremas interior emphasizes glass, warm finishes, and a clean control ecosystem that serves the marine industry. This creates a unique value proposition in your marketing, highlighting the balance between social comfort and operational efficiency. The approach supports testing and refinement of different arrangements to boost passenger pleasure and confidence in your design.

Entertainment Integration: Projector, Screen, and Gaming Lounge

Install a fixed, integrated entertainment hub in the marine saloon that combines three core components: a large projector, a glass-protected screen, and a dedicated gaming lounge, all controlled from a single interface at console level.

The control system should be designed for harsh marine conditions, with sealed enclosures and vibration-tolerant mounts. The projector is ceiling-mounted, fixed, and positioned for optimal sightlines; the screen behind tempered glass is large and fixed to resist salt, spray, and movement.

Designers should choose a centralized control panel, with intuitive switching for video sources, lighting, and audio, plus safety interlocks and surge protection. Solutions should minimize power consumption while preserving image quality, and cables should run in protected conduits to reduce wear and meet safety standards. The aim is a full-media experience without distracting guests or crew.

Required specifications include a 120–150 inch fixed screen, a 3,000–4,000 ANSI-lumen projector, marine-grade speakers, and a robust HDMI backbone with redundancy. Power management features and cooling should be tailored to the saloon’s level of use; schedule maintenance during port calls to avoid last-minute failures.

Example: on adriatico-bound yachts, designers implemented a 120-inch glass-screen setup in the saloon, with a high-brightness projector and a dedicated consoles hub; seating was arranged to keep sightlines clear, and the system ran through a single, low-latency control panel. The result: reduced glare, improved usability at sea, and reliable performance in bright conditions.

Technical Data: Dimensions, Weight, Power, and Propulsion

Recommendation: The triple-diesel propulsion with three shafts and a total of 4,200 kW maximizes security, performance, and cruising range. The nuvolari-inspired italian hull keeps weight in check, and Adler’s shipyard craftsmanship delivers a standard that yachts of this class deserve. The three engines provide powerful, controllable response; Maybe the most telling metric is the rate of fuel consumption at cruise, which stays efficient. If youre planning long passages, indulge in a steady, quiet ride that mind your facilities and safety systems, even on the most demanding routes. This ship design leaves you with a feeling of safety, while the three leaves of chine contribute to spray suppression. The project began with aviation-grade redundancy planning to ensure security in remote operation. Youre ready to change speed modes between economy and performance, and this change preserves comfort while managing consumption. This approach also always prioritizes your crew and guests, especially in challenging conditions.

Dimensions

- Length overall (LOA): 42.0 m

- Length waterline (LWL): 38.0 m

- Beam: 9.8 m

- Draft: 2.95 m

- Air draft: 14.2 m

Weight

- Lightship weight: 480 t

- Loaded displacement: 520 t

- Ballast: 40 t

- Fuel capacity: 28,000 L

- Freshwater capacity: 6,000 L

Power and Propulsion

- Total installed power: 4,200 kW (about 5,634 hp)

- Engines: 3 × 1,400 kW diesel engines

- Propulsion: 3 shafts with fixed-pitch propellers

- Gear ratio: 2.8:1

- Top speed: ~25 knots

- Cruise speed: ~22 knots

- Auxiliaries: bow thruster 210 kW; stern thruster 180 kW

- Fuel consumption at cruise: 900–1,100 L/h total

- Estimated range: 2,800–3,800 nm at 12–14 knots with full fuel

Hull and Ride Dynamics: Whisper Ride and Acoustic Management

Start with high-capacity vibration-damping mounts between the machinery cradle and the main structure to achieve vibration-free motion across the whole vessel. This aviation-inspired approach yields a calm ride at speed and keeps living spaces cool and quiet regardless of sea state.

Whisper Ride uses decoupled layers, tuned dampers, and resilient channels to isolate noise and motion from the shell to the interior. The result is a level of comfort in the helm and cabins that reduces the need for extra damping in heavy weather, particularly at mid speeds where wave interaction is strongest.

For glass areas, apply clear laminated glazing with a thickness of 20–25 mm and internal shading to preserve a clear view while minimizing sound transmission. The outcome is an environment with sharp sightlines and a quiet atmosphere inside the main living areas.

In the debut iteration of the plan, the exterior shell employs tuned mass dampers and optimized joint detailing to reduce motion transmission from waves. The quiet ride supports a focused experience in the living spaces, letting occupants work, relax, or enjoy time aboard without distraction.

| Area | Approach | Target KPI | Σημειώσεις |

|---|---|---|---|

| Main living area | Layered acoustic panels plus decoupled shell | Sound < 60 dB at 60 Hz range | Glass glazing 20–25 mm enhances clarity of view |

| Machinery cradle | High-capacity vibration-damping mounts; decoupled connections | Vibration < 0.12 g RMS at 15–25 knots | Maintains quiet operation |

| Exterior shell interfaces | Decoupled joints; reinforced stiffeners | Low-frequency transmission < 6 dB | Supports whole-boat calmness |

ADLER SUPREMA Yacht General Arrangement Plans | Adler Yacht">

ADLER SUPREMA Yacht General Arrangement Plans | Adler Yacht">