Recommendation: Choose AL SAID for a charter to secure a refined balance of engineering precision, guest comfort, and fleet-ready performance.

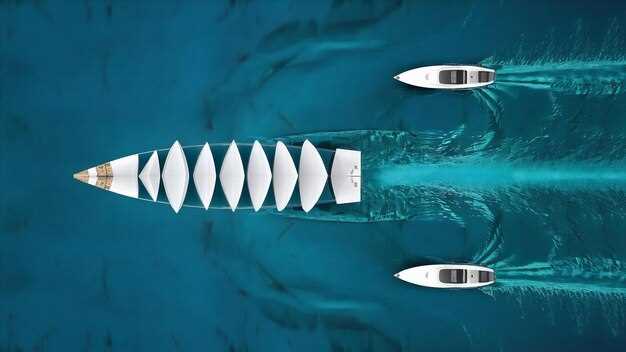

From the exterior, the lines blend understated elegance with integrated engineering that supports smooth progression at high speeds while maintaining a shallow draft to access tighter anchorages, and the silhouette nods to sail-inspired form.

Onboard, guests enjoy teak-decked decks, a grand salon with floor-to-ceiling windows, and crew facilities designed for discreet service. The interior uses integrated systems to manage climate, lighting, and entertainment with minimal energy footprint.

The yacht explores sustainability through a fuel-cell option paired with efficient propulsion, enabling cleaner operation during northern itineraries while maintaining performance.

The yacht’s sultanate-inspired finish nods to Oman’s heritage while showcasing a modern deck and interior that offers a timeless aesthetic.

For guests seeking versatility, the yacht provides expansive social zones, easy tender access from a shallow stern, and a layout that supports intimate gatherings or grand receptions during longer voyages.

AL SAID Yacht by Lürssen Yachts: Luxury Superyacht Overview

Opt for AL SAID if you want a commanding value at sea with a capable motor package and versatile exterior living spaces.

The exterior presents long sightlines, flattening hull forms, and expansive terraces that invite effortless socializing on deck. A large pool sits amid sun pads and shade, while smaller sunbathing zones on the bows provide privacy for guests.

Inside, the layout centers on guest comfort and fluid transitions between indoor and outdoor areas. Public salons, formal dining, and casual lounges connect to outdoor terraces, ensuring conversations flow between levels.

Crew and operation benefit from a well coordinated structure. Captain mohammed leads a team that can attend guests worldwide with precise timing and attentive service. The yacht underwent modification by its builder to optimize stability and crew efficiency before and after launch, and the systems are designed to operate smoothly through varying seas. Some components draw on expertise from göttingen, reflecting a robust, globally sourced supply chain that keeps the vessel well outfitted for todays voyages.

Since its launch, AL SAID has demonstrated a capacity to adapt to different itineraries, delivering a refined experience for guests on shorter getaways or longer cruises. The ambiance feels cohesive across decks, with terraces that invite social moments and a pool that remains a focal point for relaxation, even when docked or underway.

| Aspect | Details |

|---|---|

| Stavitel | Lürssen Yachts |

| Exterior design | Clean lines, glass walls, expansive terraces, pool on the main deck |

| Interior focus | Lux master suite, multiple guest salons, dining venues, versatile recreation spaces |

| Propulsion & systems | Motor propulsion with efficiency-oriented platforms; modification-friendly layout |

| Crew & service | Captain mohammed leads a well-trained team; global service footprint |

| Launch & operation | Launched recently; operates worldwide; ongoing refinements since launch |

Common Mounting of Drive and Energy Systems: Architecture and Implementation

Recommendation: Mount propulsion drives and energy systems on a single modular skid frame with integrated vibration isolation and a central service spine that provides consistent interfaces for mechanical, electrical, and hydraulic connections.

Those luxury installations benefit when that single skid holds the drive and energy systems, because it keeps the entire package entirely within a protected envelope, and those modules are designed for quick access. This design feels reliable and scales with vessel length and complexity.

Adopt a three-tier approach: platform frame, module skids, and sub-assembly blocks. The platform frame anchors the hull interface and distributes loads; module skids host drives, batteries, gensets, converters, and power electronics; sub-assembly blocks group interfaces by function and simplify maintenance. This arrangement reduces installation risk and enables future upgrades.

Key design considerations include vibration isolation, precise alignment, accessibility, liquid containment, and thermal management. Use marine-grade elastomeric or hydraulic mounts for main drives; add decouplers at transit points between compartments; ensure drip trays and bilge drainage around the machinery; provide dedicated cooling for energy gear; route plumbing and electrical cables in separate, labeled trays; implement redundant, readily accessible shut-off valves and fire-suppression interfaces.

This approach yields measurable benefits in maintenance time, fault isolation, and crew safety. The design supports those described in industry whitepapers and источники, while remaining adaptable to a range of hull forms. A referenced whitepaper notes that consolidated skids simplify commissioning and reduce total maintenance tasks. According to the pool of design options, the course length of service routes is minimized when a single spine connects all interfaces.

Layout patterns and interfaces

- Drive and energy module alignment along a common spine minimizes cabling length and improves serviceability.

- Shared service corridors with modular access doors and adequate headroom for maintenance tools.

- Lift points and palletization options to facilitate removal without disassembling the hull structure.

- Code-compliant ventilation, cooling, and fire protection integrated with each skid.

Implementační kroky

- Clarify interfaces early: mechanical, electrical, hydraulic and control signals, then generate 3-4 layout options and select the preferred arrangement.

- Choose mounting approach: fully integrated skid, semi-integrated frame, or split across adjacent compartments; specify vibration isolation ratings and load paths.

- Design service corridors: ensure generous access width and door sizes; plan for toolless panels where possible.

- Plan energy system integration: place battery racks and power electronics in ventilated, fire-rated compartments; segregate energy storage from fuels; connect to a centralized energy bus with clear disconnects.

- Route and manage cables and lines: standardized trays, color-coding, reserved spare length, and surge protection; implement fire-stopping and drip containment.

- Test and commission: verify tolerances, run dynamic and thermal tests, confirm redundancy functions and emergency shutoffs.

Technologies and risk management

- Hybrid power architectures combine diesel or gas turbines with battery packs and shore-power; these technologies reduce engine room noise and improve fuel efficiency in luxury operations.

- Battery racks and energy management systems should be modular, allowing swaps without full crew retraining; these pools yield shorter downtime during maintenance.

- Thermal management pairs active cooling with thermal energy storage to maintain stable operating temperatures for drives and power electronics.

Industry context and sources

On luxury projects, including rising Saudi deployments, the modular mounting approach has gained traction due to easier service access and reduced total weight. These considerations align with stated design goals in many whitepapers and источники; по whitepaper they yield better maintainability and safer access across areas known as engine rooms, power zones, and electronics decks. According to the pool of options, the total length of service routes is minimized when a single spine connects all interfaces. These patterns are developed and designed to adapt to the course length of luxury yachting applications where access is critical and occupant feels are preserved, ensuring those aboard feel comfort and security.

System Layout and Key Interfaces

Implement a centralized, modular system hub on the main deck near the bridge to streamline operations for a superyacht. It will create a unified platform that ties propulsion, power management, HVAC, navigation, and onboard communications, all connected by a corrosion-resistant backbone. Cable routes extend across meters of hull space, with labeled trays and drop-down panels to simplify troubleshooting and future upgrades. This setup supports cruising and offshore operations, while keeping the crew focused on safety and comfort.

Key interfaces include the bridge console for course and speed control; engine-room touch panels with live parameters; electrical-distribution panels; and climate-control interfaces integrated with the interior management unit. aera cooling for critical electronics, and a dedicated media and communication node, enable onshore and onboard connectivity. Include status icons, alarms, and clear navigation paths to avoid cross-cabling. The system should follow a common protocol that aligns with the builder’s design philosophy, ensuring brands work together smoothly.

The interior and exterior interfaces stay cohesive: touchpoints in the bridge, crew mess, galley, and tender bays share the same interface language. The design uses a modular hardware box that can be expanded as the superyacht undergoes refits. The builder can select brands known for reliability; a clean surface reduces clutter while delivering features such as remote monitoring, consumption readouts, and maintenance alerts. Other integration points, like watermakers, fire-suppression, and ballast control, tie into the central system so the crew can react before a situation escalates.

Power distribution and energy strategy present clear data: the system powers propulsion thrusters and hotel load, with a reserve path for critical equipment. Onboard sensors track voltage, current, and battery health, while the design anticipates consumption patterns during cruising and at anchor. Provide enough headroom in the power bus to handle surge conditions, and ensure the interface surfaces show real-time data in meters and other units, with minimal navigation to avoid distraction. For offshore passages, the control suite supports course corrections and contingency actions without leaving the helm.

Maintenance and training focus on reliability: the crew training plan covers daily checks, fault diagnosis, and routine software updates. The builder and service partners should supply a spare parts map and a service window to undergo updates with minimal downtime. Include a detailed interior map of connections and access panels to support quick repairs in any sea state. Also ensure the system supports offline diagnostics when satellite comms are down.

Hybrid Power Sources: Batteries, Generators, and Electric Drives

Recommendation: Deploy a modular hybrid package with a 2.5–3.5 MWh battery bank, a 1.0–1.3 MW genset, and high‑efficiency electric drives, tuned for live optimization, shore‑power access, and recovery during docking on adriatic itineraries.

Battery systems provide limitless sets of operating modes. For large vessels, target 2.5–4.0 MWh of usable capacity by a modular 250–500 kWh block strategy. Choose lithium‑ion chemistries such as NMC or LFP with a future path toward solid‑state options, and support with bio-based coolants and lubricants as they mature. Position the pack midship to minimize weight transfer under teak decks and keep a live monitoring loop on cell voltages, temperatures, and pack impedance to protect the total system integrity.

Gensets provide robust running capability when batteries are drained or peak power is needed. Use two gensets at 0.8–1.2 MW each for a vessel in the 60–90 m range, with a 1.0–1.5 MW option for larger yachts. Run them on diesel or bio‑based fuels to cut lifecycle emissions, and integrate a waste‑heat recovery system to pre‑heat feedwater and support a hot‑water loop during lengthy passages, boosting overall efficiency by 10–15%.

Electric drives enable silent operation and precise handling. Implement two electric motors totaling 2.0–3.0 MW driving azimuth or tunnel thrusters, with DP readiness for heavy seas. Pair the drives with the battery bank to allow electric‑only transit at low speeds and shore‑power powered operation when docked, keeping fuel burn low and crew comfort high. An energy‑management system links the batteries, gensets, and propulsion to deliver steady power while presenting live dashboards to the captain and Rashid’s integration team.

Operationally, the hybrid layout suits adriatic routes and shipyards that craft these craft in teak‑lined decks. The approach reduces noise, emissions, and fuel costs, with rising demand among smaller and larger superyachts for alternative energy solutions that scale with needs. Access to shore power and proven DP configurations help integrate the system into existing layouts for these craft.

For Rashid and the team, this path combines a robust battery pack, efficient gensets on bio‑based fuels, and smart drives that live with a single operating philosophy across a vessel of this scale. The total energy footprint shrinks as usage patterns shift toward battery‑first operation, and the gross emissions figure drops with optimized charging cycles. This configuration remains flexible, offering limitless options to tailor sets of profiles for different sea states, total mission duration, and access to shore power while keeping the adriatic horizon in clear view.

Energy Management: Charging, Distribution, and System Coordination

Use a centralized EMS to coordinate charging, distribution, and system operations. Tie shore power, gensets, battery banks, and propulsion drives to a common bus with fast-acting protection and bidirectional charging. For lurssen superyachts, this enables precise load prioritization during guest and crew operations. Map loads by mission: hotel services, propulsion, watermakers, and media, then apply a real-time priority scheme so essential systems stay online while nonessential loads are shed during peak demand. This approach aligns with features seen on columbus vessels and is scalable for escort and speedboat support roles. источник.

Charging strategy: implement a battery-first energy architecture with modular banks sized for peak loads and recovery events. Use a three-tier charging plan: regular shore-power fills in port, generator-backed charging at sea with peak shaving, and opportunistic storage when energy is available from HVAC heat recovery. Keep SOC targets around 20-95% to minimize aging, avoid long sustained extremes, and extend battery life. Use bidirectional chargers to enable energy recovery from propulsion torque or HVAC during dwell times. For emissions, choose components with aftertreatment compatibility and bio-based lubricants where feasible to support a cleaner luxury operation.

Distribution architecture: deploy a modular, multi-bus system with essential and nonessential loads separated. Implement 400V AC main buses and 48V DC microgrids for high-power systems like HVAC, desalination, and lighting, with automatic transfer switches between shore, genset, and battery sources. Use smart breakers and digital protection to keep critical systems–navigation, bridge, safety, life-support–online during transitions. Design for redundancy so a loss of one genset or shore tie does not interrupt operations on a given mission, whether close to shore or during a voyage toward arabia or qaboos regions. This has been proven on lurssen builds and other superyachts, and remains flexible for columbus-class projects and even escort or speedboat support roles.

Coordination and planning: feed the EMS with predictive load models based on guest schedules, climate, galley activity, and media demands. Schedule charging during low-tariff windows and periods of high renewable availability, and use heat-recovery loops to pre-warm cabins and hot water. Tie engine exhaust aftertreatment data to the EMS to optimize idle efficiency and ensure compliance. Use this data to craft energy-service terms for owners, captains, and yards, so the system adapts to different duty cycles and climates. The result is a user-friendly tool that preserves beauty and reliability across yachts under this profile.

Operational tips: maintain a living EMS rulebook with lessons learned from voyages, and monitor performance against recovery targets to adjust charging curves. Train crew to interpret EMS alerts and perform quick reconfigurations during port calls or escort duties. Keep maintenance aligned with the aftertreatment system and bio-based fluids to minimize downtime. The aim is a well-orchestrated energy ballet that keeps the superyacht energized, closer to design targets, and ready for every journey.

Safety, Redundancy, and Maintenance Access

Install a dual-path maintenance corridor with a reinforced hatch on the port side to reach engine rooms, switchgear rooms, and ballast tanks from interior stairs and the exterior deck. This well-planned layout delivers immediate access during routine checks, inspections, or emergencies, and it results in a faster, safer response across marinas and anchorages worldwide.

Redundancy architecture should be documented and tested regularly. Key elements to implement include:

- Electrical back-up: twin generator sets, independent fuel feeds, and automatic transfer switches with cross-linked bus bars that let one path carry critical loads while the other remains idle for maintenance.

- Propulsion and steering: a spare hydraulic pump, an alternate seawater cooling loop, and a second steering motor with quick-access service panels to minimize downtime after faults.

- Fire and smoke safety: a zoned, remotely controllable suppression system with manual pull stations at two decoupled locations, plus dedicated fire panels in the galley, engine room, and crew areas.

- Communications and navigation: a second VHF/DSC channel and a separate data backbone that keeps essential systems alive if the primary line is compromised.

- Seawater and bilge management: independent pump circuits with check valves, plus a dedicated ballast and dredge-safe drain path that can be isolated quickly to prevent flooding.

Maintenance access must be practical for the crew and guests alike. Aim for connections that stay accessible through the life of the yacht, not just at handover. The existing framework should be reviewed at major milestones (launch, first year, and every two years thereafter) to confirm no issue surfaces that could affect safety or uptime. A robust plan will fit in the large footprint of a vessel like AL SAID, with careful attention to exterior routes and interior compartments.

Access design specifics you should implement now:

- Exterior accessibility: watertight doors, safe catwalks, and non-slip surfaces on all main deck levels to support routine checks in any weather; ensure these routes connect to service corridors without requiring disassembly of living areas.

- Interior corridors: clearly marked paths to engine rooms, battery rooms, and the greenhouse-like climate-control spaces where electronics and batteries stay within target temperatures; include bright lighting, handrails, and quick-release panels for fast removal when needed.

- Maintenance cells and panels: modular, fitted units that allow technicians to remove a single panel without exposing adjacent equipment; use labeled, color-coded fasteners to speed reassembly during a busy port call.

- Through-hull accessibility: inspection ports and shut-off valves placed in protected cages that crew can reach safely from a dedicated deck or maintenance deck, reducing risk during hull work or ballast service.

- Battery and electrical rooms: battery cells stored in a climate-controlled greenhouse-like module with a separate ventilation circuit and gas detection; keep spare cells and related consumables in a nearby locked cabinet.

- Ventilation and climate control: a redundant HVAC loop that maintains stable humidity and temperature on all critical equipment decks; monitor sensors remotely and display alarms in the bridge and crew lounge.

To minimize issues during ongoing operation, incorporate a clear naming system and documentation. Each space should carry a concise nameplate, a door silhouette, and a one-page quick-guide describing the main procedures for isolation, testing, and return to service. This approach helps the crew execute routine checks with confidence, whether the yacht sits through the day in a sun-drenched marina or moves across the world on long passages.

Operational discipline matters. Regular drills, a two-person rule for critical tasks, and a standing checklist for maintenance access work keep the effort focused and predictable. In practice, the combination of well-planned paths, fitted redundancy, and dedicated maintenance cells reduces downtime and supports a smooth launch-to-cruise transition. This approach aligns with the vessel’s built-in strength, supports a large crew, and ensures the safety of guests and crew alike as the sultanate of Oman and other destinations beckon.

Hull Integration and Impact on Weight, Space, and Handling

Start with an integrated hull plan that couples hull form, ballast strategy, and propulsion layout to control weight and center of gravity from the outset. For these saudi and sultanate–oriented projects, this approach keeps guest spaces at the forefront while preserving performance. A coordinated team (including a partner such as Tankoa when applicable) aligns structural tolerances with interior objectives, ensuring the boat delivers on life safety, comfort, and accessibility. Running conditions and docking scenarios take center stage early, so the hull is designed to behave predictably in both calm seas and rough passages.

Aluminum hulls reduce weight, enabling more room for guest spaces and reducing overall displacement. These less heavy hulls ease structural demands, improving stability at rest and during running. Aluminum also improves corrosion resistance and supports longer spans with welded frames, which means fewer stiffeners and more efficient interior layouts–so the spaces aimed at guests become truly usable without compromising strength. The properties of the material enable larger window openings and natural light, a key factor in livability for long voyages.

Weight distribution and tank layout drive handling and trim. Place heavy items such as fuel and water tanks along the centerline and near the keel to minimize trim moments, including ballast tanks that can be adjusted for load and sea state. This strategy reduces pitch and roll under running conditions, making the biggest yachts feel more responsive at speed and when maneuvering in tight harbor slots. These choices often involve close collaboration with lurssen teams and, if chosen, the tankoa solution to keep interfaces clean and predictable.

Windows and interior volumes demand careful structural integration. Large windows boost life onboard but require optimized glazing frames and lightweight yet strong supports. The properties of glazing, frame alloys, and sealants must balance daylight penetration with thermal performance and safety. Aluminum frames help keep weight down while preserving stiffness, so guests enjoy bright cabins without compromising hull integrity.

Propulsion and handling hinge on the placement of drive equipment. Turbines or hybrid diesel-electric packages introduce significant mass that must be balanced along the centerline to minimize heel and reduce vibration transmission to living spaces. A hull designed to accommodate these systems supports smoother acceleration, steadier tracking, and better control in crosswinds, contributing to a more comfortable guest experience when the boat is on long passages.

Lurssen’s history includes delivering vessels to demanding markets in the saudi region and sultanate clients, where hull integration takes life in every deck, cabin, and guest area. The biggest yachts in this lineage show how a seamless blend of hull, deck, and superstructure can deliver calm motion, generous spaces, and a confident feel at sea. These projects take on a holistic approach, ensuring every kilogram of weight is purposeful and every cubic meter of space serves owner and guest needs, even under challenging conditions.

Takeaways: aim for a hull that utilises aluminum to drop weight, implement flexible ballast systems, and preserve window and space usability. Coordinate closely with a partner network to prevent schedule slippage, keep costs predictable, and ensure delivered performance aligns with life onboard expectations, whether the client is Saudi or from a neighboring market. This approach positions the boat to balance speed, comfort, and safety while sustaining a lasting, luxurious experience for guests and crew alike.

AL SAID Yacht by Lürssen Yachts | Luxury Superyacht Overview">

AL SAID Yacht by Lürssen Yachts | Luxury Superyacht Overview">