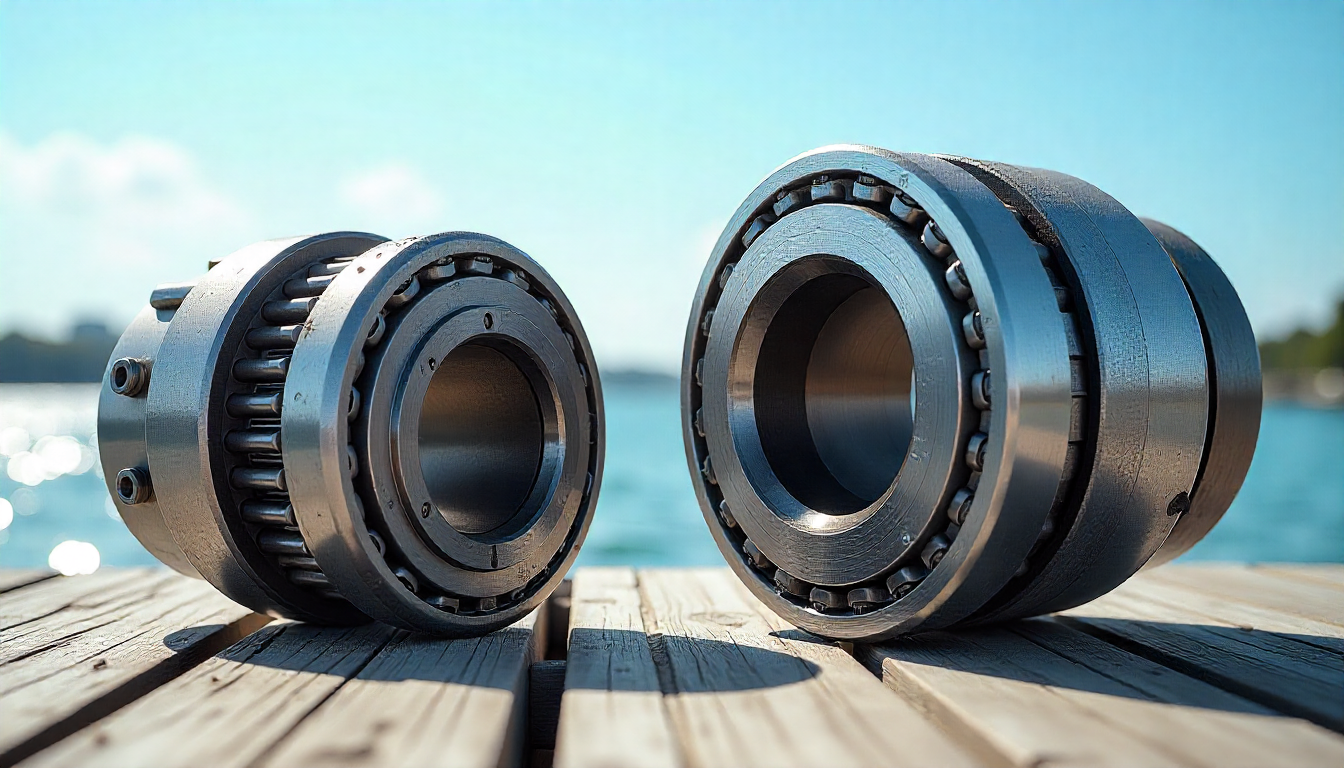

When it comes to smooth performance and durability, boat owners often face the challenge of deciding between inboard vs outboard bearings. The choice directly affects efficiency, maintenance costs, and long-term performance. Understanding the strengths and weaknesses of both systems helps people make informed decisions, especially when the motor setup can influence not only handling but also overall comfort.

The Difference Between Inboard vs Outboard Bearings

Boat design determines whether inboard and outboard motors are installed, and each requires a different type of bearing system. Inboard bearings are fitted along the propeller shaft inside the hull. On the other hand, an outboard bearing connects directly to an external motor unit at the rear. Both serve the same purpose: reducing friction, absorbing loads, and ensuring that the shaft rotates smoothly.

How Inboard Bearings Work

Inboard bearings are located inside the hull, supporting the propeller shaft as it transfers power from the motor. The bearing is typically water-lubricated, which helps avoid overheating. Since the inboard motor is mounted within the boat, the bearing placement allows for quieter operation. However, servicing requires a mechanic to access parts that are less visible.

How Outboard Bearings Work

An outboard bearing functions differently. It sits directly within the compact motor system, providing support for the shaft extension and propeller. Outboard units are easier to service since the entire motor can be lifted off. That convenience is one reason people use outboard setups in smaller boats. The downside is that they may wear faster, especially in saltwater conditions, where constant flushing is required.

Maintenance Needs of Inboard and Outboard Bearings

Maintenance is one of the clearest areas where differences emerge.

Inboard Bearing Maintenance

Inboard bearing systems require regular checks to avoid shaft misalignment. Since the components are located inside, it may be harder to detect issues until vibration or noise becomes noticeable. Still, the inboard setup is more or less protected from constant exposure to saltwater. This means inboard parts tend to last longer with proper care.

Outboard Bearing Maintenance

On the other side, an outboard bearing demands much more frequent flushing and greasing. Exposure to marine growth and corrosion means these parts are much less durable unless consistently maintained. For weekend boaters who like quick access and easy servicing, the outboard option is attractive, though long-term costs may be higher.

Performance Considerations

Performance depends on both the motor and the bearing setup.

Inboard Performance

An inboard motor with properly aligned bearings ensures smooth torque transfer and reduced vibration. This translates into better fuel efficiency over long distances. Since the motor is positioned lower, weight distribution often feels right for larger vessels. However, docking in tight spaces may feel less agile.

Outboard Performance

An outboard motor, supported by its bearing system, gives quick responsiveness and improved maneuverability. It is easier to tilt and adjust, helping boats go into shallow waters. The tradeoff is that bearing outboard systems experience more direct stress, leading to potential wear sooner.

Costs and Long-Term Value

Inboard Costs

The upfront cost of inboard systems is higher, but they last longer when maintained. The bearing replacement intervals are extended, and many owners see them as an investment.

Outboard Costs

In contrast, bearing outboard units may need replacing sooner, but the parts are cheaper. Many boat owners like the flexibility of upgrading the entire motor instead of servicing individual bearings. For smaller boats, this means less hassle and quicker turnaround.

Safety and Reliability

Safety on the water often depends on whether bearings can handle high loads without failure.

- Inboard bearings generally handle higher stress levels since they are built for larger boats.

- An outboard bearing works well for lighter vessels where maneuverability is more important than brute strength.

We recommend that people carefully think about their boating style before choosing.

Which Is Better – Inboard vs Outboard Bearings?

The debate over inboard vs outboard bearings does not have a single answer.

- If you want a low-maintenance, long-lasting solution and have a larger vessel, inboard bearings are the right way to go.

- If you need flexibility, easy servicing, and enjoy boating in shallower waters, an outboard bearing may suit you better.

Since every boat owner’s needs are different, the choice depends on whether durability or convenience matters most.

Common Misconceptions

Some people think one system is always better than the other, but that is not entirely true.

- An inboard bearing isn’t maintenance-free. It still needs regular alignment checks.

- An outboard bearing isn’t automatically weak; with proper care, it can last long enough for most casual users.

- Everyone has seen boats that overperform expectations simply because their owners kept up with maintenance.

الأفكار النهائية

Choosing between inboard and outboard bearings means weighing performance, cost, and maintenance. While both serve the same fundamental purpose, the environment in which they operate makes all the difference. A professional mechanic can help assess wear, but ultimately, the decision is personal.

If you’re unsure, think about how often you go boating, where you go, and how much effort you want to put into long-term care. Since maintenance is the key to avoiding big repair bills, whichever setup you choose, take the time to inspect and service it regularly.

The right bearings keep your motor smooth, efficient, and reliable—ensuring that your time on the water is safe and enjoyable.

Inboard vs Outboard Bearings – Which Type Is Best for Your Boat?">

Inboard vs Outboard Bearings – Which Type Is Best for Your Boat?">